Table of Contents

- Overview of the CCR (Continuous Catalyst Regeneration) Process

- What is a CCR Blower? Basic Definition

- What Does the CCR Blower Unit Do?

- CCR Blower Working Principle

- 1. Air Intake (Inlet Phase)

- 2. Air Compression by Rotor Rotation

- 3. Sending Pressurized Air to the Regeneration Column

- 4. Temperature Resistance and Thermal Stability

- 5. Continuous Operation Mode

- CCR Blower Unit Design Features

- 1. Heat-Resistant Material Structure

- 2. Specially Designed Rotor and Blade Geometry

- 3. High-Durability Bearing and Bearing System

- 4. Ex-Proof and Safety Certifications

- 5. Pressure and Flow Control Mechanisms

- 6. Low-Vibration Operation and Noise Optimization

- 7. Modular Design for Easy Spare Parts and Service

- How is CCR Blower Unit Maintenance Performed?

- 1. Daily Operational Checks

- 2. Weekly/Monthly Routine Maintenance

- 3. Periodic Replacement of Bearings and Lubrication System

- 4. Rotor and Internal Surface Checks

- 5. Calibration of Sensors, Instruments, and Control Systems

- 6. Motor Maintenance

- 7. Annual Comprehensive Maintenance (Overhaul)

- Frequently Asked Questions About the CCR Blower

- 1. Are CCR blowers and reformer blowers the same thing?

- 2. Why is the CCR blower specially manufactured?

- 3. How is CCR blower capacity calculated?

- 4. What happens if the CCR blower fails?

- 5. What is the maintenance interval for a CCR blower?

- 6. What material is the CCR blower made of?

- 7. Does the CCR blower consume a lot of energy?

- Conclusion – The Heart of Petrochemical Continuity: CCR Blower

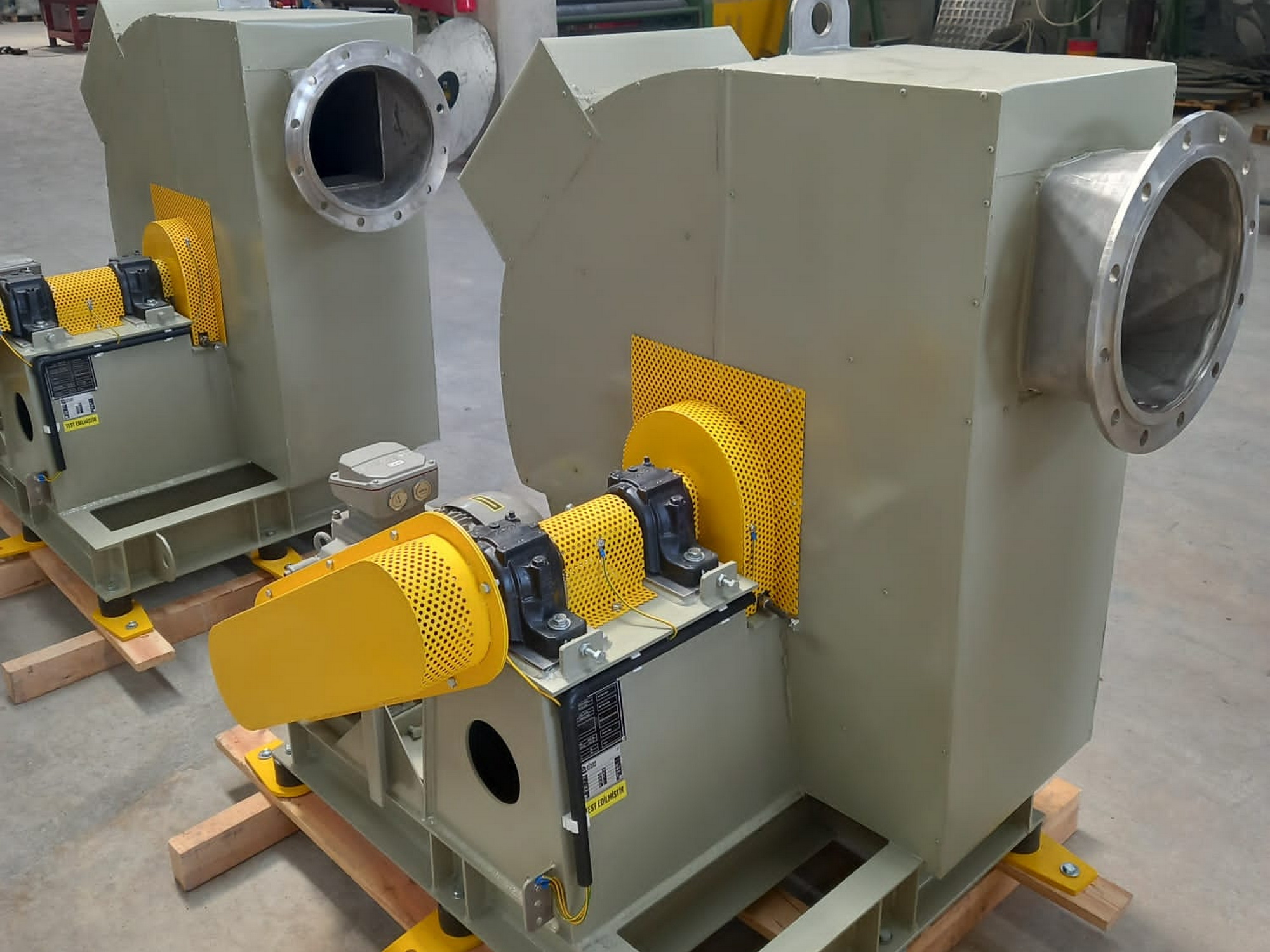

Every piece of equipment used in petrochemical plants has a specific function; however, some play a critical role in ensuring process continuity and safety. The CCR Blower is one such piece of equipment. In Continuous Catalyst Regeneration (CCR) units, the catalyst must be continuously regenerated, which requires the supply of air at the correct volume, temperature, and pressure. This task is performed by the CCR Blower Unit, which is designed to withstand high temperatures, corrosive gases, and heavy process loads. What is a CCR Blower? Everything About Its Working Principle, Functions, and the CCR Blower Unit

The CCR blower is one of the most critical points in the cycle between the reformer and regenerator. Even the slightest change in the air flow can directly affect catalyst regeneration, production efficiency, and plant safety. Therefore, the proses gas blower is a specialized piece of equipment that requires a high level of expertise in both engineering design and performance requirements.

Regeneration Blower

You may find this article interesting. Comprehensive Guide to Industrial Fan Types and Their Applications

Overview of the CCR (Continuous Catalyst Regeneration) Process

Catalysts used in petrochemical plants lose their activity over time, which reduces product quality and negatively impacts process efficiency. While traditional systems require production to be halted for catalyst regeneration, CCR (Continuous Catalyst Regeneration) technology makes this process completely seamless. This preserves high production capacity while significantly reducing operational costs.

The CCR unit is a closed-loop system that continuously regenerates the catalyst exiting the reformer reactor. In this loop, the catalyst passes through stages such as drying, chlorination, oxidation, and cooling, returning to the process with its activity restored. One of the most critical points in this cycle is the controlled air flow required during regeneration.

This air flow is essential for the correct reaction to occur during the oxidation stage of the catalyst. If the air flow rate, pressure, and temperature are not controlled, the regeneration balance is disrupted and the entire process is affected. For this reason, at the heart of CCR systems is a piece of equipment designed specifically for the process: the CCR Blower.

The CCR blower enables continuous catalyst renewal by delivering the required amount of air to the regeneration column with high precision. Therefore, the CCR blower is not just an air blowing device, but also a critical control element for process stability.

What is a CCR Blower? Basic Definition

CCR Blower is an industrial blower type specially designed to withstand high temperatures and aggressive process conditions, providing the air flow necessary to sustain the catalyst regeneration process in the Continuous Catalyst Regeneration (CCR) unit. Although it may look like a simple fan, it is actually a precision engineering equipment that plays a critical role in process safety and efficiency.

The air sent to the regeneration column in the CCR system must be at the exact flow rate and pressure to ensure that the reactions in the oxidation stage of the catalyst are carried out correctly. Therefore, the CCR blower does more than just transport air; it ensures that the air flow is stable, controlled, and fully compliant with process requirements.

Since proses gas blower must withstand harsh conditions such as high temperatures, continuous operation, exposure to corrosive environments, and pressure changes, they are generally composed of:

- Special alloy steels,

- High-temperature resistant bearing systems,

- Low-vibration rotor designs,

- Ex-proof (explosion-proof) options.

In short, the CCR blower is the equipment that provides the oxidation air required for the continuity of catalyst regeneration and is the heart of the CCR unit. Without this equipment, regeneration cannot be performed.

In short, the proses gas blower is the equipment that provides the oxidation air required for continuous catalyst regeneration and is the heart of the CCR unit. Without this equipment, the regeneration cycle cannot be completed, process efficiency decreases, and production may be interrupted.

What Does the CCR Blower Unit Do?

CCR Blower Unit is the main power unit that supplies the necessary oxidation air to the regeneration column in the CCR process, where the catalyst is continuously regenerated. This air enables the controlled burning of carbon deposits on the catalyst surface and the restoration of catalyst activity. Therefore, the CCR blower unit is the main component that maintains the “continuous regeneration” feature of CCR technology.

The main functions of the CCR blower unit are as follows:

1. Provides the Air Flow Required for Catalyst Oxidation

The oxidation stage is the most critical step in which the active structure of the catalyst is restored. If the air flow is insufficient, regeneration will be incomplete; if it is excessive, thermal imbalance will occur. The CCR blower unit controls this delicate flow with millimeter precision.

2. Maintains Process Pressure and Flow Balance

In the CCR process, constant pressure is a prerequisite for stable combustion and correct reaction. The blower unit ensures that the pressure balance in the regeneration column remains stable. This is critical for process safety.

3. Guarantees Uninterrupted Operation in High-Temperature Environments

CCR units operate in areas with temperatures reaching up to 450–500°C. The CCR blower unit is designed to operate continuously for long periods under these conditions. It is not without reason that the industry saying “if the CCR blower stops, regeneration stops” exists.

4. Contributes to Energy Efficiency

The rotor, body, and motor designs used in modern CCR blower units enable higher performance with lower energy consumption. This reduces plant operating costs.

5. Increases Process Safety

A malfunctioning CCR blower can cause:

- Overheating,

- Incorrect oxidation reactions,

- Pressure imbalances,

- Plant shutdowns

Therefore, the blower unit is not just an air source, but also one of the safety barriers of process control.

Lift Gas Blower

CCR Blower Working Principle

The working principle of the CCR blower is based on an air compression cycle designed for high-temperature processes. The purpose of this cycle is to ensure that the air sent to the regeneration column is maintained at constant flow rate, stable pressure, and controlled temperature values. The operating principle of the CCR blower consists of a combination of fluid mechanics, thermodynamics, and process control technology.

1. Air Intake (Inlet Phase)

The CCR blower draws air from an air inlet line connected to the atmosphere or the process. This air must be:

- Filtered,

- Humidity controlled,

- Inlet pressure stabilized

because the stability of regeneration reactions is directly related to the quality of the inlet air.

2. Air Compression by Rotor Rotation

The rotor located at the center of the blower rotates at high speed. As the rotor blades push the air outward by centrifugal force, the air is compressed and its pressure increases. CCR blowers are generally designed to use:

- Radial (centrifugal) blower,

- High temperature resistant rotor body,

- Vibration reduction balancing technology

.

This allows both high pressure to be generated and stable flow to be maintained throughout the process.

3. Sending Pressurized Air to the Regeneration Column

The compressed air is delivered to the regeneration column through a specific flow control valve. This air flow initiates the chemical reaction required for the oxidation stage of the catalyst.

- If the pressure drops, oxidation will be insufficient.

- If the pressure rises, the catalyst may be damaged.

Therefore, the outlet control of the CCR blower is a critical engineering parameter.

4. Temperature Resistance and Thermal Stability

CCR processes can reach temperatures exceeding 400–500°C. For this reason, the blower is manufactured with components such as:

- High-temperature steel,

- Special bearing materials,

- Thermally expansion-tolerant body

.

It also features control systems that automatically balance the outlet pressure against temperature changes.

5. Continuous Operation Mode

CCR systems are processes that operate 24 hours a day without interruption. Therefore, the CCR blower:

- Features a design that does not require downtime,

- Has low maintenance requirements,

- And offers high endurance

to provide uninterrupted support for the continuous regeneration cycle.

CCR Blower Unit Design Features

The CCR Blower Unit is an advanced engineering product specifically designed to withstand harsh conditions such as high temperatures, continuous operation requirements, and corrosive process gases. The design of these blowers is much more comprehensive than standard process blowers and is tailored to the critical needs of petrochemical plants. The key design features that make CCR blower units unique are detailed below.

1. Heat-Resistant Material Structure

Temperatures in CCR processes can reach 400–500°C. Therefore, the blower casing and rotors are manufactured from:

- Heat-resistant alloy steels,

- Metal composites that tolerate high-temperature expansion,

- Structural materials reinforced against thermal fatigue

.

This ensures that the blower does not experience deformation or performance loss during long-term operation.

2. Specially Designed Rotor and Blade Geometry

CCR blower rotors feature a special aerodynamic design to achieve high pressure and constant flow. The rotor blades:

- Minimize vibration during high-speed operation,

- Are tolerant to thermal expansion,

- Are optimized to reduce pressure loss.

This design increases process stability while reducing energy consumption.

3. High-Durability Bearing and Bearing System

Bearing systems are one of the most common failure points in petrochemical processes. The bearings used in CCR blower units:

- Have high-temperature lubrication capacity,

- Can operate under excessive load,

- Have a special structure that is resistant to corrosion.

Magnetic bearing technology can also be used in some models.

4. Ex-Proof and Safety Certifications

Since CCR blowers operate in areas where explosive atmospheres are possible, they are typically certified to:

- ATEX,

- IECEx,

- API (process compatibility)

standards.

This ensures the blower provides a safe structure against risks such as gas leaks or static charge.

5. Pressure and Flow Control Mechanisms

Since pressure changes are critical in the CCR process, blower units are equipped with advanced control modules:

- Variable frequency drives (VFD),

- PID-based pressure control systems,

- Sensor-based temperature–pressure monitoring modules.

These features ensure that the blower operates intelligently and in full compliance with process requirements.

6. Low-Vibration Operation and Noise Optimization

Since CCR blower units operate continuously, vibration levels are critical. Therefore, the design includes:

- Dynamic balancing,

- Anti-vibration mounting feet,

- Aerodynamic rotor symmetry.

This reduces maintenance requirements and extends the blower’s lifespan.

7. Modular Design for Easy Spare Parts and Service

Modern CCR blower units have a modular body structure. This allows:

- Bearing replacements,

- Rotor removal procedures,

- Coating renewals

to be performed much faster.

Plant downtime is minimized.

How is CCR Blower Unit Maintenance Performed?

As the CCR blower unit is one of the most critical pieces of equipment in petrochemical plants, its maintenance is of great importance for uninterrupted process safety. A CCR blower that is not properly maintained can cause serious malfunctions due to high temperatures, vibration, corrosion, and pressure imbalances. The following maintenance practices ensure that the blower operates with a long service life and high performance.

1. Daily Operational Checks

These quick checks performed by operators play a critical role in early failure detection:

- Monitoring outlet pressure, temperature, and flow rate values

- Checking vibration levels

- Verifying that motor current values are within normal range

- Observing for any unusual noise, odor, or vibration

These checks enable the early detection of deviations that affect process efficiency.

2. Weekly/Monthly Routine Maintenance

This period involves a more detailed maintenance process where the condition of mechanical components is examined:

- Measuring bearing temperatures

- Checking oil levels

- Cleaning filters

- Checking coupling alignment

- Inspecting suction and discharge lines for blockages

These steps are necessary to prevent sudden failures.

3. Periodic Replacement of Bearings and Lubrication System

Since CCR blowers operate at high temperatures, bearings are the most stressed components. Therefore:

- A lubricant suitable for high temperature class should be used

- The lubrication period should be applied according to the manufacturer’s recommendation

- Bearing noise and vibration analyses should be performed

If this maintenance is not performed, bearing damage can lead to blower shutdown.

4. Rotor and Internal Surface Checks

In CCR processes, air can sometimes interact with chemical components. Therefore:

- Rotor wear and deformation check

- Anti-corrosion coating surface inspection

- Monitoring of rotor blade balance

must be performed. Deformations on surfaces destabilize air flow.

5. Calibration of Sensors, Instruments, and Control Systems

The CCR blower unit operates with modern process control systems. Therefore:

- Pressure sensors

- Temperature sensors

- Flow meters

- VFD (Variable Frequency Drive) parameters

must be calibrated periodically.

Even a small deviation in the control system can disrupt the oxidation process.

6. Motor Maintenance

The motor is the blower’s most important power source. Motor failures are generally caused by:

- Phase imbalance

- Overloading

- Weakened insulation

Therefore, the following should be performed regularly for the motor:

- Insulation resistance measurement

- Coil temperature control

- Phase current analysis

7. Annual Comprehensive Maintenance (Overhaul)

This maintenance is usually performed during planned shutdown periods at the facility:

- Bearing, coupling, and gasket replacements

- Rotor balancing

- Internal casing coating renewal

- Complete overhaul of the motor

- Re-tightening of all fasteners

Annual maintenance ensures trouble-free operation of the blower for the following year.

Frequently Asked Questions About the CCR Blower

Since the CCR blower is critical equipment in petrochemical plants, engineers, maintenance teams, and purchasing departments frequently ask many technical questions about it. Below, we provide clear and technically accurate answers to the most common questions.

1. Are CCR blowers and reformer blowers the same thing?

No.

A reformer blower is a piece of equipment that transports hydrocarbon mixtures in the reforming process.

A CCR blower, on the other hand, is a specialized unit that provides the oxidation air required for catalyst regeneration.

The operating environment, pressure requirements, and material structures of the two pieces of equipment are completely different.

2. Why is the CCR blower specially manufactured?

Temperatures in the CCR process reach 400–500°C, and the reaction chemistry is highly sensitive. Therefore, the blower must:

- Be resistant to high temperatures,

- Be protected against corrosion,

- Maintain a constant flow rate and pressure for long periods,

- Be explosion-proof.

Standard blowers cannot withstand these conditions.

3. How is CCR blower capacity calculated?

The following parameters are considered in the capacity calculation:

- Required air flow rate (Nm³/h),

- Outlet pressure (kPa or mbar),

- Process temperature,

- Pressure losses in the regeneration column,

- Pipeline length and resistance.

The blower’s rotor characteristics and motor power are determined based on these values.

4. What happens if the CCR blower fails?

If the CCR blower stops, the regeneration cycle also stops. This situation can cause:

- A decrease in catalyst activity,

- A decrease in reformer efficiency,

- Process instability,

- Plant shutdown

. For this reason, CCR blowers are usually installed in a stand-by configuration.

5. What is the maintenance interval for a CCR blower?

The maintenance interval varies depending on operating conditions, but generally:

- Daily: Operational checks

- Monthly: Mechanical inspection

- 3–6 months: Bearing and lubrication check

- 12 months: Comprehensive maintenance (overhaul)

A maintenance plan is implemented in this manner.

6. What material is the CCR blower made of?

Generally:

- High-temperature steels (AISI 310S, Inconel derivatives),

- Corrosion-resistant alloys,

- Thermal expansion-tolerant materials

are used. These materials provide both chemical resistance and long life.

7. Does the CCR blower consume a lot of energy?

Since CCR blowers operate continuously, their energy consumption is important. However, in modern blowers:

- Efficient motors (IE3–IE4),

- Aerodynamic rotor designs,

- Low-loss air flow

are used, so energy performance is highly optimized.

Conclusion – The Heart of Petrochemical Continuity: CCR Blower

The CCR blower is one of the most critical components of petrochemical plants and is the essential equipment that enables Continuous Catalyst Regeneration (CCR) technology to operate efficiently. The quality of the air flow supplied to the regeneration column plays a directly decisive role in catalyst activity, reformer efficiency, and the plant’s overall production performance. Therefore, the CCR blower is not just an air blower, but a strategic control point for the sustainability and safety of the process.

A CCR blower that is selected with the correct capacity, manufactured with high-temperature resistant materials, and supported by advanced control systems

- ensures stable catalyst regeneration,

- increased energy efficiency,

- minimized failure risks,

- and reduced plant downtime.

Just like the heart, which must function continuously and regularly, even the smallest problem with this equipment can affect the entire process chain. Therefore, the design, selection, maintenance, and operation processes must be handled by a professional engineer.

Just like the heart, even the smallest problem in this equipment, which must operate continuously and regularly, can affect the entire process chain. Therefore, the design, selection, maintenance, and operation processes require a professional engineering approach.

As a result, if process continuity, efficiency, and safety are targeted in the petrochemical industry, the CCR blower is a fundamental technology that must be prioritized in investment planning.

tags :

More about the sector and our business