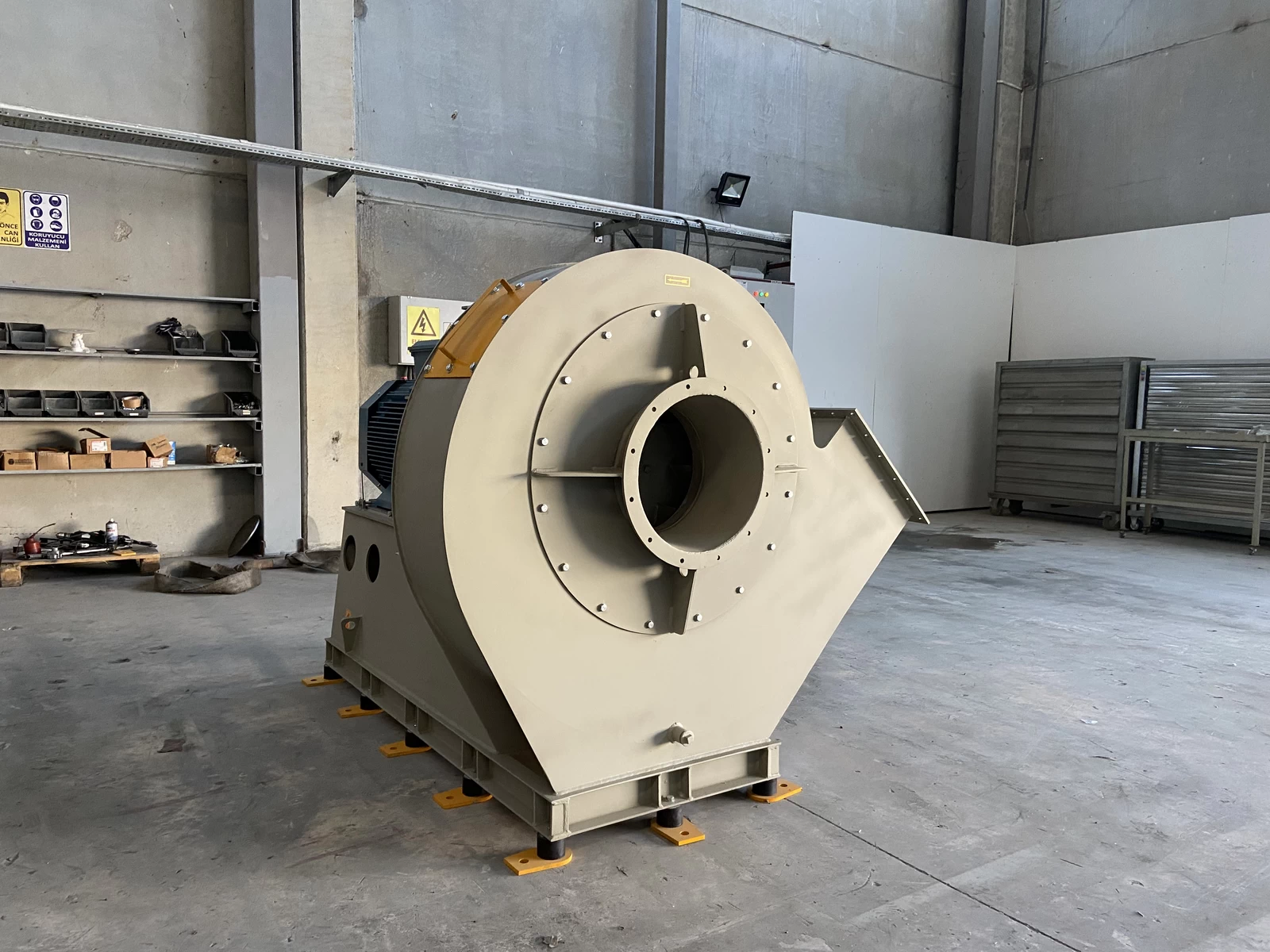

Ex-Proof Fan / Blower

Explosion-proof fans used in hazardous environments where explosive gases or dusts may be present.

“Explosion Proof” means equipment manufactured in accordance with standards such as ATEX or IECEx , which prevents situations that may cause an explosion such as sparks, overheating.

25 Years of Experience and Engineering to Manage the Air

Ex-Proof Fan / Blower: Maximum Safety and Performance in Hazardous Environments

Explosive atmospheres pose a serious risk to industrial installations. The mixture of flammable gases, vapors, mists or dusts with air creates potentially hazardous environments where even a small spark can cause a devastating explosion. Fan and blower systems used in such areas must be designed and manufactured in accordance with the highest safety standards.

As Efsan Makina, we design and manufacture ATEX certified and IECEx compliant Ex-Proof (Explosion Proof) Fans and Blowers. Our goal is to ensure that you do not compromise the operational efficiency of your facility while ensuring safe management of air in hazardous areas. Our products are specially engineered to prevent sparking, prevent overheating and provide complete protection against external factors.

Why Should You Prefer Efsan Makina Ex-Proof Fan / Blower?

- Absolute Safety Certification: Our products are certified in full compliance with the European Union’s ATEX directives and international IECEx standards. This guarantees the highest level of safety in hazardous environments.

- Special Material Selection and Design: We ensure maximum safety with features such as non-sparking materials (e.g. brass or aluminum propellers), static dissipating paints, sealing elements and special bearing housings.

- Process Specific Solutions: We offer solutions tailored to the specific hazard level and requirements of each process (Zone 0, 1, 2 for gas; Zone 20, 21, 22 for dust).

- Engineering Depth: With years of experience and expertise in hazardous environments engineering, we design for optimum safety and performance in even the most complex projects.

- Comprehensive After Sales Support: Starting with installation, periodic ATEX inspections, maintenance, spare parts and technical support, we ensure the safe and efficient operation of your unit throughout its lifetime.

Control the risk of explosive atmosphere in your facilities with Efsan Makina Ex-Proof Fan and Blower units and ensure safety and operational efficiency together. Contact us for project-specific solutions.

Our Ex-Proof Fan and Blower units play a critical role in all enclosed or semi-enclosed areas where there is a risk of explosive atmosphere:

- Ventilation: Area ventilation to prevent accumulation of chemical vapors, solvent gases or combustible dust.

- Process Gas Transfer: The safe transportation of hazardous gases from one point to another.

- Exhaust Systems: Evacuation of flammable or explosive gases, vapors and dusts from production areas.

- Pressurization Creating positive pressure in hazardous areas to prevent the entry of explosives from outside.

- Deodorization: The safe removal of odors from flammable and harmful gases.

Our Ex-Proof Fans and Blowers are widely used in various industries where safety standards must be kept at the highest level:

- Oil and Gas Refineries: Crude oil processing, storage tanks, pumping stations and gas treatment units.

- Chemical Industry: Facilities for solvent production, processing of paints, resins, pharmaceuticals and other chemical products.

- Pharmaceutical Industry: Ventilation of dusty or solvent vapor environments and process air management.

- Food Industry (Dusty Environments): Places where there is a risk of explosive dust such as flour mills, sugar processing plants, spice production areas.

- Painting and Coating Plants: Painting and drying booths where flammable vapors and solvents are concentrated.

- Mining: Underground and surface mining sites where explosive materials such as methane gas and coal dust are present.

- Waste Management and Recycling: Biogas plants, solvent recovery units and waste treatment areas where flammable gases are generated.

Our Ex-Proof Fan and Blower units are offered with our integrated engineering approach and comprehensive service approach:

- Engineering / Design / Optimization: Aerodynamic and mechanical solutions to prevent sparking and overheating, tailored to the ATEX zone classification and specific needs of your project.

- Installation / Commissioning: Safe and correct on-site assembly of your unit, installation in accordance with ATEX guidelines, pressure tests and risk assessment, and trouble-free commissioning.

- Maintenance / Service / Spare Parts Service: Uninterrupted and safe operation with regular periodic maintenance, ATEX inspections, troubleshooting and supply of original, certified spare parts.

- Test / Measurement Service: Post-installation performance tests, vibration, sound and tightness measurements, reporting to international standards and verification of ATEX compliance.