Table of Contents

- How to Ensure Efficiency in Industrial Fan Manufacturing?

- Manufacturing Approaches to Increase Resilience

- From Design to Assembly: Industrial Fan Manufacturing Process

- How to Choose the Right Fan Manufacturer?

- The Difference in Industrial Fan Manufacturing with Efsan Makina Approach

- Make a Difference in Production with the Right Fan Selection

The Role of Industrial Fans in Factories. Breath of Industry: Why Industrial Fans are Indispensable

In modern production facilities, every detail is crucial for efficiency and continuity. However, one element that is often overlooked is the industrial fan systemsthat allow the factory to breathe. From food plants to cement factories, from chemical plants to power plants, these fans play critical roles in terms of both safety and production quality.

Industrial fan manufacturingis not just about producing a device that blows air. It requires engineering solutions tailored to the needs of the production line, optimizing airflow and maximizing energy efficiency at the same time.

Fans ensure the uninterrupted operation of production processes with a variety of tasks such as dust extraction, gas evacuation, ambient cooling, drying or fresh air supply. Choosing an industrial fan for factories is therefore not only a choice of equipment, but also a production strategy.

In today’s industrial environment, the need for highly efficient and durable industrial fans is greater than ever. In this period when energy costs are increasing and environmental sustainability has become a necessity, businesses can achieve both environmentally friendly and economical solutions with properly designed, engineering-strong fan systems.

In this article, we will cover all aspects of the industrial fan manufacturing process, focusing on efficiency and durability; we will examine in detail how quality production is possible, which engineering principles are applied and what advantages are provided to businesses by choosing the right manufacturer.

Industrial Fan Manufacturing

How to Ensure Efficiency in Industrial Fan Manufacturing?

How to Produce High Efficiency Industrial Fans?

The performance of industrial fans directly affects the production process. Therefore, an efficiency-oriented manufacturing approach is critical both to reduce energy consumption and to ensure long life and stable operation of the system.

1. Aerodynamic Design and Fluid Mechanics

High efficiency starts with the blade design that provides the right air flow. The blade inclination, opening angle and surface shape in the internal structure of the fan minimize air friction, resulting in higher flow rate and less energy consumption. Such calculations are optimized with CFD (Computational Fluid Dynamics) software.

2. Material Selection and Fan Type Matching

The sector and ambient conditions in which the fan will be used (high temperature, dusty air, chemical vapors, etc.) determine the type of fan to be selected (radial, axial, plug fan, etc.) and the material quality. For efficiency, low resistance and high strength materials suitable for the structure should be preferred.

3. Motor and Drive Technology

Instead of conventional AC motors, EC motor technology offers higher performance with less energy thanks to variable speed control. In addition, inverter drives integrated into the fan system automatically adjust the fan speed according to the required air flow rate. In this way, energy savings of up to 30% can be achieved.

4. Quiet and Vibration-free Operation

An efficient fan must also offer low noise levels and vibration control. Unbalanced blades or incorrect balancing not only reduces performance but also shortens system life. Therefore, balance tests and vibration measurements should be carried out in production.

5. Smart Fan Systems

In the new generation fans, the operating data of the fan can be monitored instantly by using sensor-supported control systems and remote-access automation modules. In this way, both energy consumption and risk of failure are minimized.

Efficiency is possible not only with engineering know-how, but also with a production approach that is sensitive to sectoral needs. At this point Efsan Makina companies with high engineering capability, such as the company’s Engineering Center, support the efficient operation of factories by developing solutions tailored to specific project needs.

Industrial Fan Production

Manufacturing Approaches to Increase Resilience

Quality, Material and Test Standards for Industrial Fans

Industrial fans are equipment that are expected to operate smoothly for years in harsh production environments. Therefore, it is not enough to be efficient; they also need to be highly durable. Every detail in the manufacturing process directly affects the life and performance of the fan.

1. Choosing the Right Material

Durability starts with the material used in the fan’s body and blade structure.

- Sheet steel or stainless steel is preferred in corrosive environments.

- In high temperature or chemical vapor environments, special coated or alloyed metals are used.

- Aluminum or composite materials can also be used for lightweight yet durable solutions.

2. Quality Control and Testing Processes in Fan Production

Industrial fans must undergo many tests after production:

- Static and dynamic balance tests: Reduces vibration and extends bearing life.

- Acoustic testing: Supports work safety by measuring the noise level.

- Thermal endurance tests: Shows whether there is deformation or loss of performance in fans exposed to high temperatures.

- Air flow and pressure tests: Checks that the performance of the fan is in accordance with the technical data.

3. Certification and Compliance with Standards

A reliable industrial fan must be manufactured in accordance with national and international standards.

- Quality certificates such as ISO 9001, CE, TSE

- ATEX certificate (for exproof fans to be used in explosive atmospheres)

- Special norms for the food or chemical industries (hygienic design, anticorrosive structure, etc.)

4. Long-lasting Design and Serviceability

Another factor that increases durability is ease of maintenance.

- The modular design enables fast parts replacement and on-site repair.

- Spare parts availability and after-sales technical support ensure system sustainability.

- Parts such as the fan motor, bearings and connection systems should be positioned for easy maintenance.

In short; durable industrial fan production is possible not only with the right material, but also with advanced engineering tests, quality control processes and a long-lasting design approach.

By systematically implementing these processes, engineering-oriented manufacturers such as Efsan Makina both increase efficiency in production and provide long-term cost advantages to businesses.

From Design to Assembly: Industrial Fan Manufacturing Process

How to Design a Factory-Specific Fan?

Each production facility has its own unique needs according to its structure, ambient conditions and production line. For this reason, industrial fan manufacturing does not fit into a standard mold. To build a truly efficient and durable system, the entire process, from design to assembly, must be handled on a factory-specific basis.

1. Exploration and Needs Analysis

The manufacturing process starts with site reconnaissance and technical assessment.

- Criteria such as ambient temperature, air flow rate requirement, particle density, humidity are determined.

- Energy infrastructure, installation area, existing ventilation systems are analyzed.

- The targeted air flow and direction are optimized according to the operation of the production line.

2. Special Fan Design and Projecting

Fan type is determined according to the analysis results:

- Axial fan or radial fan?

- High pressure or high flow rate?

- Is there a need for an explosion-proof structure?

Fan design is modeled in 3D with CAD and CFD supported software. In this way, air flow simulations can be made and performance analysis is performed before the system enters the production phase.

3. Manufacturing and Quality Control

The fan housing, blades and motor components are manufactured in accordance with the selected materials.

- CNC controlled cutting, bending and welding processes ensure precise production.

- Static and dynamic balance adjustments are made after production.

- Each fan is tested and certified according to the relevant standards.

4. Assembly and Commissioning

The commissioning of the fan system requires as much expertise as its installation on site.

- The modular fan design ensures easy installation and minimal production downtime.

- During assembly, the alignment of the fan motor, insulation of the connection points, installation of anti-vibration feet are carefully carried out.

- Flow rate measurements and safety checks are performed at the first start-up, ensuring full compatibility of the system with the production line.

5. Remote Monitoring and Automation Integration

Modern fan systems integrate with PLC or SCADA to automatically adapt to the production process.

- Flow and pressure values can be monitored with sensors.

- Remote error alerts can be received.

- Speed can be controlled by frequency converter to save energy.

Thanks to this end-to-end engineering approach, industrial fan systems become a strategic part of the production line, not just a ventilation tool. Manufacturers with a strong engineering infrastructure, such as Efsan Makina, work in integration with the customer at every stage and offer industry-specific fan solutions.

high efficiency industrial fan systems

How to Choose the Right Fan Manufacturer?

Things to Consider When Investing in Industrial Fans

Industrial fans are critical to keep production processes running efficiently and safely. But in addition to the right design and manufacturing, working with the right fan manufacturer guarantees long life, economic and trouble-free operation of the system.

Here are the main criteria to consider when investing in fans:

1. Technical Expertise and Experience

The sectoral experience of the fan manufacturer is directly proportional to its ability to offer solutions.

- In which sectors did he develop projects before?

- Which engineering tools (CFD, CAD, test systems) are used in the production facility?

- Does it carry out processes such as site exploration, project design and installation in-house?

With its experience in different sectors, Efsan Makina embraces this process from start to finish and offers project-specific engineering solutions.

2. Domestic Production Advantage

Working with producers based in Turkey;

- Short lead times,

- Access to spare parts,

- On-site technical support,

- And it provides great convenience in terms of cost advantage.

Domestic production also eliminates the exchange rate risk and reduces foreign dependency.

3. Certificates and Quality Documents

Products from a trusted manufacturer must carry the following documents:

- ISO 9001 Quality Management System

- CE Certificate

- ATEX special safety certificates such as (in explosive atmospheres)

- Related sector-specific test reports

These certificates certify production quality and reliability.

4. After Sales Services

The value of a fan is not limited to its production.

- Technical service network

- Care services

- Spare parts supply

- Periodic control and reporting services are important for the sustainability of the system.

At this point, Efsan Makina stands by its customers with 24/7 technical support and on-site intervention.

5. Reference Projects and Customer Satisfaction

It tells about a good manufacturer, past projects and customer reviews.

- Sectors and businesses that the company has served before

- Scope and success level of completed projects

- Feedback from customers

Efsan Makina is a brand that has proven its engineering power in the field with reference projects realized in Turkey and abroad.

Fan investment is a long-term strategic decision. For this reason, it is important to choose a manufacturer that focuses not only on price but also on technical competence, reliability and sustainability.

The Difference in Industrial Fan Manufacturing with Efsan Makina Approach

The Meeting Point of Efficiency, Durability and Trust

Efsan Makina is not only a fan manufacturer, but also a business partner that understands production processes and offers a solution-oriented engineering approach. It is one of the companies that make a difference in the sector with its technical knowledge, project experience and production capability.

Project Based Engineering Approach

Every production facility is different. Efsan Makina takes these differences into consideration;

- On-the-spot discovery,

- Customized design,

- Selection of the appropriate fan type,

- It develops project-based solutions with stages such as CFD analysis and prototyping.

In this way, businesses get customized solutions that can be integrated into their own production lines, not standard products.

Broad Sectoral Experience

Efsan Makina has developed a deep expertise in industrial fan manufacturing with projects in many different sectors:

- Special snail fans for cement plants, high dust load and temperatures

- Power plants, large diameter radial fans

- Hygienic and quiet fan solutions for the food industry

- Recycling and chemical plants, exproof and corrosive resistant systems

- Stainless fan systems suitable for marine, salty and humid environments

End-to-End Service Model

One of the most important points where Efsan Makina makes a difference is that it offers a service model that embraces the entire process, not just production:

- Fan design and manufacturing

- Test and measurement services

- Assembly and commissioning

- After-sales technical support

- Periodic maintenance and performance improvement recommendations

This holistic approach guarantees the operational continuity of businesses.

Energy Efficiency and Technology Integration

Efsan Makina produces not only durable but also energy efficient and smart fan systems:

- Designs compatible with EC motors and frequency inverters

- PLC/SCADA integration

- Automatic speed control

- Remote monitoring and diagnostics support

These solutions provide businesses with significant energy savings and ease of operational control.

Efsan Makina’s approach to industrial fan manufacturing represents an understanding that supports production with reliable and efficient solutions where engineering turns into practice. With its competence in fan production specific to each sector, it presents a vision that meets not only today’s needs but also tomorrow’s needs.

Make a Difference in Production with the Right Fan Selection

Strategic Manufacturing for Long-Lasting, Efficient and Safe Fan Systems

For businesses that want to increase their competitiveness in today’s industry, choosing the right equipment at every stage of production is of great importance. In this context, industrial fan manufacturing is not just a machine production; it is a strategic process that directly affects efficiency, energy management, safety and continuity.

The right fan, not just the air;

- Job security,

- Energy savings,

- Production quality,

- And it brings sustainability.

For this reason, businesses should definitely seek answers to the following questions when choosing an industrial fan:

Is my fan system suitable for the real needs of my business?

Are energy-efficient technologies available in this system?

Can the manufacturer offer me a customized solution with its engineering infrastructure?

Is my fan system sustainable in terms of ease of maintenance and spare parts support?

Strong Production Steps with Efsan Makina

Efsan Makina not only answers all these questions, but also becomes a part of the solution at every stage, from site survey to after-sales support.

- Customized fan design for your factory

- Tested and certified products

- Modern energy-saving systems

- Maximum continuity in production with engineering assurance

Conclusion:

The right investment in an industrial fan system is critical not only for today, but also for your future production capacity, energy costs and system safety.

Businesses working with Efsan Makina gain not just a fan but a long-lasting and highly efficient production solution supported by industrial engineering.

Industrial fans are powerful air-handling devices used to control the ambient air in factories and large production facilities. Their main tasks are:

- Ventilation: Providing clean and fresh air in closed production areas, protecting the health of employees and improving the production environment.

- Gas and Dust Evacuation: To expel harmful gases and dust generated in chemical, cement or recycling plants, to increase occupational safety.

- Temperature Control: Regulating the ambient temperature to prevent overheating in power plants and machine rooms.

- Drying and Cooling: To assist in the drying and cooling of products in the food and textile industries.

- Pressure Stabilization: Supporting the stable operation of production processes by controlled direction of air flow.

In short, industrial fans are critical infrastructure elements for uninterrupted, safe and efficient production processes.

Industrial fans are divided into different types according to their intended use and design features. In general, the main fan types are as follows:

- Axial Fans:It moves the air in the direction of the fan axis. Used in high flow, low pressure applications. Ideal for ventilation and cooling.

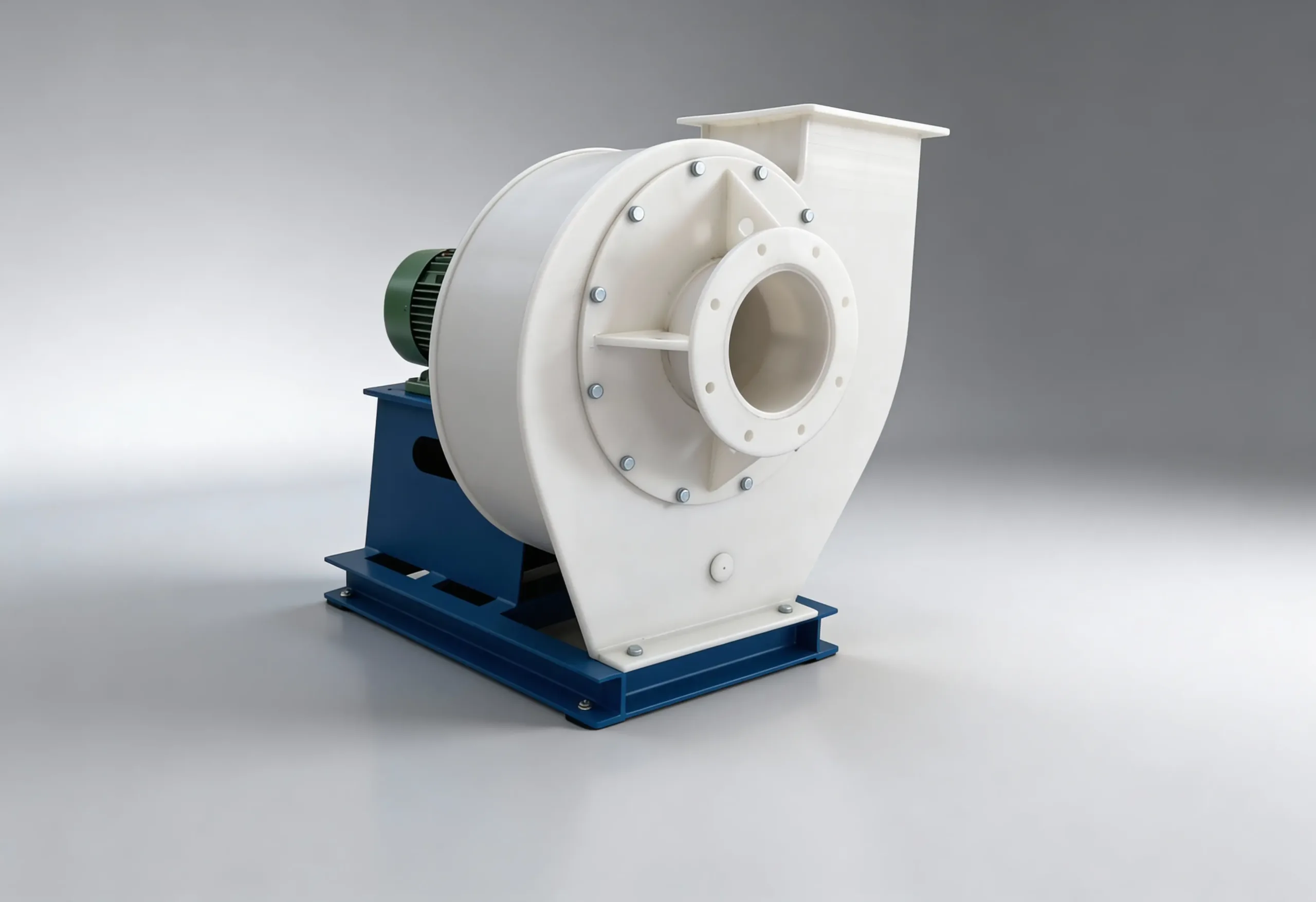

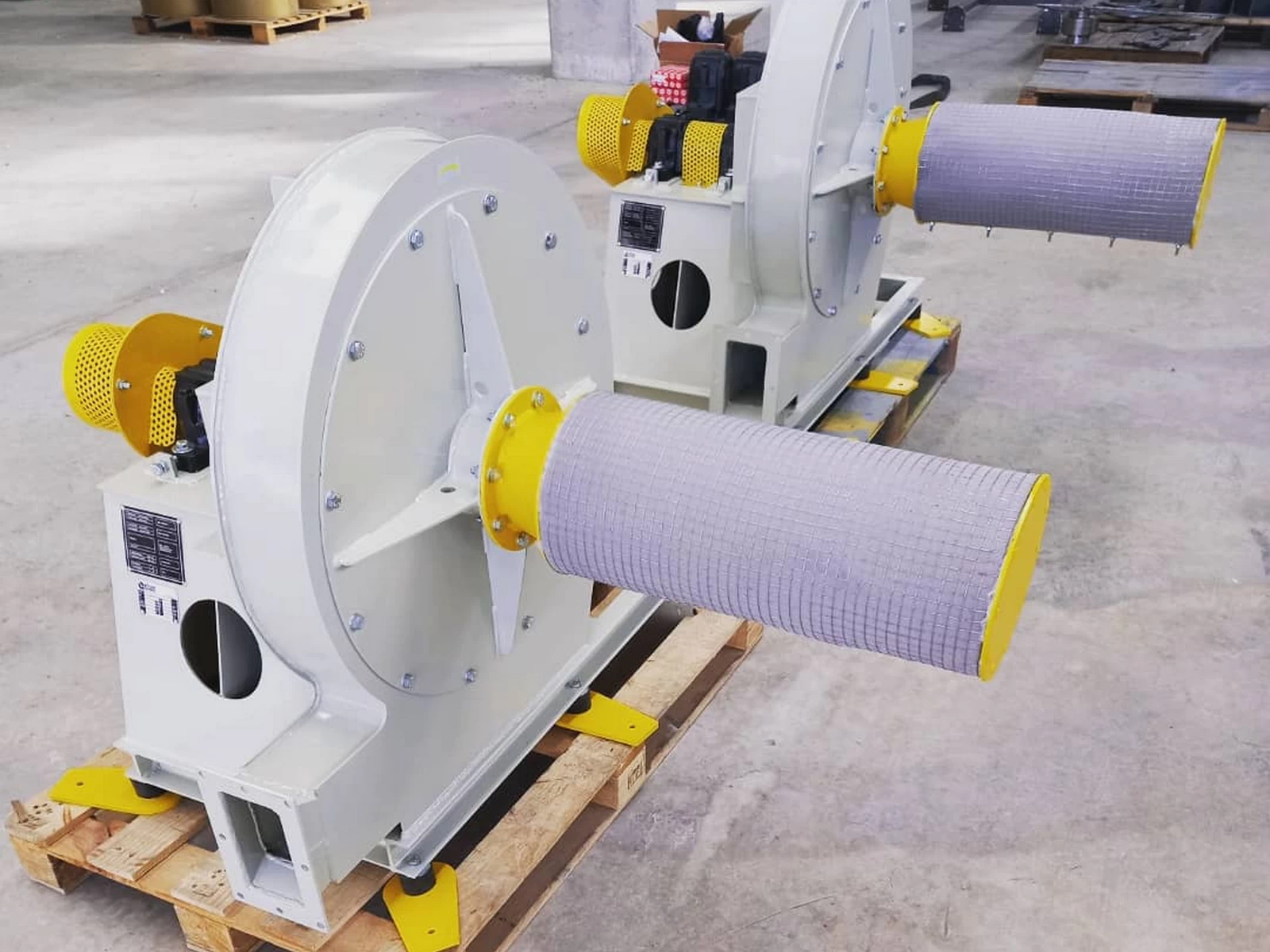

- Radial (Snail) Fans:It takes the air from the fan center and removes it outward in a radial direction. It is preferred in industrial applications requiring high pressure and low flow rate.

- Plug Fans:Although similar to the axial fan type, it provides high performance and efficiency thanks to its special design. Generally used in HVAC systems.

- Roof Fans:Axial or radial fans mounted on the roof, generally used for ventilation.

- Eccentric Fans:Special fans designed for flexible applications that can direct air at different angles.

- Exproof Fans:ATEX certified, non-sparking fans for safe use in explosive gas and dust environments.

- Centrifugal Fans:It belongs to the group of radial fans and creates high pressure. Used in heavy industry sectors such as chemistry, cement, energy.

Apart from these basic types, there are also different special fan types depending on the area of use and technical specifications. Which fan to choose depends on ambient conditions and needs.

Three-phase fan is a type of industrial fan powered by a three-phase electric motor. Three-phase motors provide higher power, efficiency and durability than single-phase motors. For this reason, three-phase fans are preferred in large-scale industrial applications and in fan systems that require high flow and pressure. Thanks to its powerful motor structure, it offers uninterrupted and stable operation for a long time. Widely used in factories, power plants or production facilities.

Exproof fans are non-sparking and ATEX certified fans specially designed for use in explosive gas or dust environments. These fans comply with high safety standards to prevent the risk of fire or explosion in hazardous areas. These fans are compulsorily preferred in production facilities with explosive atmospheres in the chemical, petrochemical, paint and food industries.

An axial fan is a type of fan that moves air along the fan blades, i.e. in the axial direction (not radial). It is generally preferred in applications requiring high flow rate and low pressure. Axial fans are designed to provide large volumes of air movement and are used for cooling, ventilation and humidity control. It is widely used in many industries with its lightweight structure and easy installation advantage.

A radial fan is a type of industrial fan that takes the air flow from the center of the fan, and with the rotational movement of the blades, the air is discharged to the side surface of the fan, that is, in the radial direction. These fans are preferred in applications requiring high pressure and low flow rates. They are widely used in cement factories, mines and chemical plants, especially in dusty, dirty or dense air conditions. Radial fans are suitable for harsh industrial environments thanks to their robust construction and high durability.

Industrial fan is a powerful fan system designed to perform operations such as ventilation, cooling, gas or dust evacuation in large volume areas with high air flow and pressure generation capacity. It is used in industrial environments such as factories, workshops, production facilities and regulates the ambient air, protecting employee health and ensuring that production processes continue safely and efficiently.

tags :

More about the sector and our business