Table of Contents

- What is Pressure in Fans and Why is High Pressure Important?

- What is a High Pressure Fan and in Which Processes is it Used?

- Dust-Free Environment Criteria: Under What Conditions Should High Pressure Fan Operate?

- The Hidden Cost of Incorrect Fan Selection: Process Downtime and Losses

- Pushing the Boundaries with Single-Stage Engineering

- Meet the Right Engineering Before Your Production Stops

The hidden culprit behind capacity drops and unexpected shutdowns in industrial production lines is often miscalculated ventilation systems. If you can’t provide enough combustion air to your furnaces or are experiencing blockages in your pneumatic lines, the permanent solution you’re looking for is a high pressure fan selected with proper engineering.

What is Pressure in Fans and Why is High Pressure Important?

In industrial fans, pressure is the fundamental driving force that allows air or gas to move through the duct, overcoming friction, bends, filter resistance, and system losses. It is divided into static and dynamic pressure.

In axial fans, static pressure is needed to “overcome resistance” when air needs to pass through narrow ducts or dense filters. Pushing fresh air into a furnace’s combustion chamber (combustion air) or pushing material through a long pipeline depends entirely on the high pressure the fan can generate.

What is a High Pressure Fan and in Which Processes is it Used?

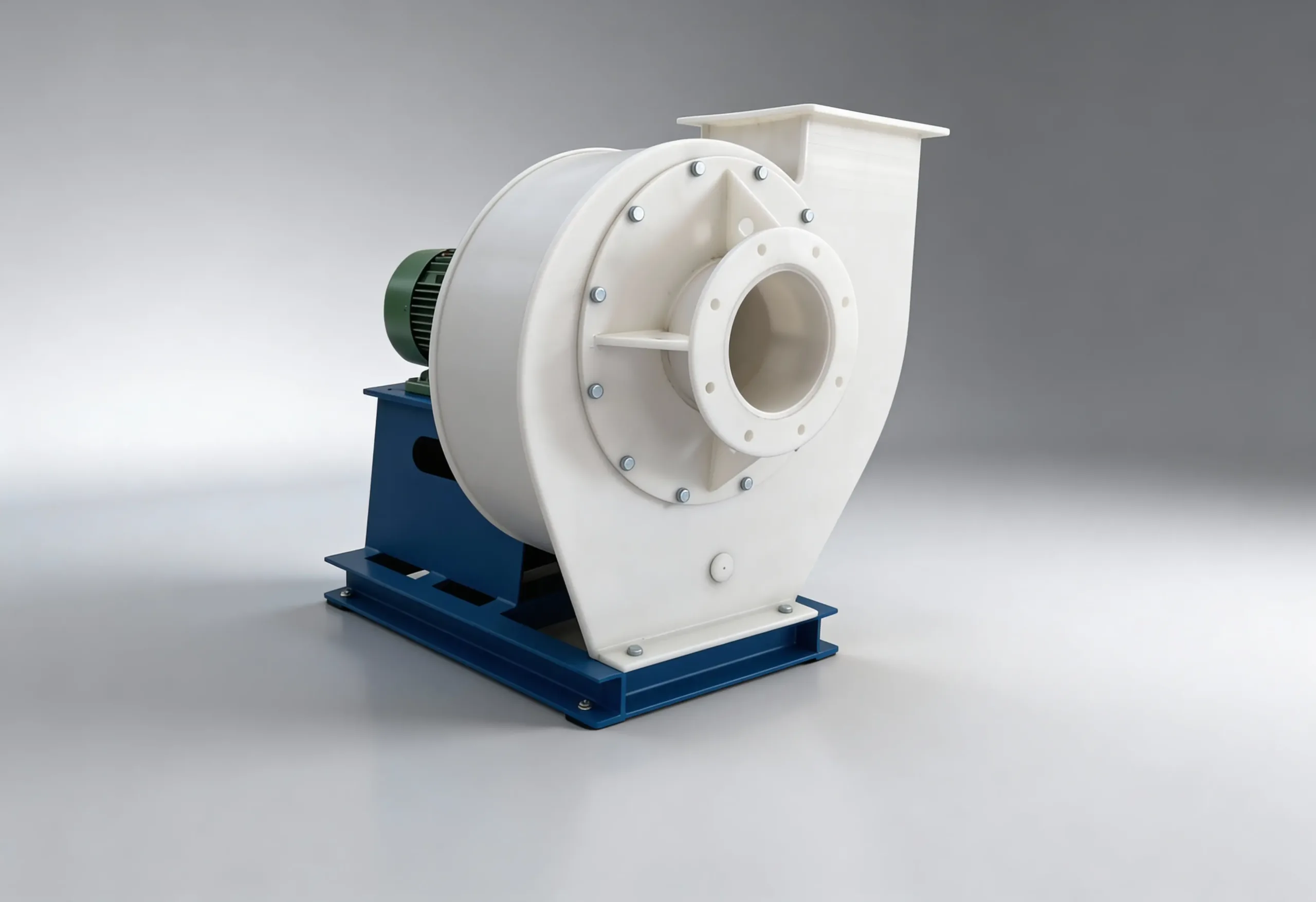

A high pressure fan is a type of specially designed industrial radial fan that achieves very high static pressure even at low or medium airflow rates, ensuring uninterrupted airflow through long ducts and resistive systems.

Their narrow blade structures and wide, high-speed impellers give them enormous centrifugal force. Especially in the cement, iron and steel, and glass industries, the supply of combustion air, gas exhaust, and the operation of cyclone systems are entirely dependent on the aerodynamic performance of these fans.

This article might interest you. Primary Air Fan (High Pressure Fan) Working Principle, Advantages and Maintenance Guide

Dust-Free Environment Criteria: Under What Conditions Should High Pressure Fan Operate?

High-pressure radial fans, due to their narrow blade spacing and very high motor speeds, must absolutely be operated in clean (dust-free and particle-free) airflows. Otherwise, high-speed particles will disrupt the fan’s balance.

A common problem in the field is confusing the applications of standard dust extraction (transfer) fans with those of high-pressure process fans. When attempting to pass granules, sawdust, or heavy dust through a high-pressure fan, these materials strike the impellers at enormous speeds, leading to severe wear and deadly vibrations. If dusty air is present in the system, it must be cleaned by passing it through a filter or cyclone system before reaching the fan.

The Hidden Cost of Incorrect Fan Selection: Process Downtime and Losses

Investing in a fan with incorrectly calculated capacity and pressure values leads to furnace failures or production line shutdowns. The resulting daily operating loss far exceeds the fan’s own purchase cost.

One of the most painful scenarios we’ve seen in practice for years is ordering fans based solely on catalog data or “approximate” values obtained by rote. However, when the system’s actual static pressure is not taken into account, the fan chokes the moment it’s connected to the line. The result: a non-functioning furnace, a halted production line, and tens of thousands of dollars wasted time.

To avoid such a scenario, you should definitely have your system thoroughly examined by a team of expert engineers before proceeding to the ordering stage. The wrong fan isn’t just a cheap fan; it’s the most expensive mistake that can shut down a factory.

The table below clearly shows the real cost difference between standard fans purchased simply because they are “cheap” and engineered solutions specifically designed for the process’s resistance:

| Investment Criterion | Wrongly Chosen Fan | Efsan Engineered Fan | Result / Impact |

| Initial Purchase Cost | Low | Optimized | A standard fan seems cheap initially but causes long-term losses. |

| Meeting System Pressure | Unpredictable (usually insufficient) | 100% Process Compatibility | The standard fan chokes, the furnace fails to operate, or the line clogs. |

| Energy Consumption (kWh) | High (Motor is strained) | Productive (Aerodynamic efficiency) | The custom-designed fan amortizes the initial investment difference in electricity bills within months. |

| Process Downtime Risk | Very High | Minimum | The cost of a single day of production downtime is exponentially higher than the fan’s own price. |

Pushing the Boundaries with Single-Stage Engineering

High pressure values, achievable only with multi-stage fans or bulky blowers in traditional systems, can be reached without loss at levels of 45 kPa (450 mbar) and above in a single stage thanks to our special aerodynamic design.

According to industry standards, businesses are generally expected to install multi-stage systems that take up much more space, consume more energy, and are difficult to maintain for these pressure levels. However, thanks to the rotor dynamics and special housing designs developed by Efsan Engineering, we reach this enormous pressure stably with a single centrifugal fan. This provides your business with:

- Low Energy Consumption: Reduced motor friction losses.

- Compact Design: Significant space savings within the facility.

- Minimum Maintenance Cost: Provides the advantage of long-lasting operation with fewer moving parts.

Meet the Right Engineering Before Your Production Stops

There’s no room for chance or assumptions in your industrial processes. Any step taken without determining exactly what flow rate and pressure (in Pascals/Pa) your system needs is a potential crisis.

At Efsan, we don’t just try to fit standard products off the shelf to your system. We analyze your project’s requirements on-site and design fans from scratch that operate according to dust-free principles and perfectly match your specifications.

To avoid wasting time and money on the wrong fan selection, contact the Efsan engineering team immediately.

tags :

More about the sector and our business