Table of Contents

Many efficiency issues related to airflow in industrial facilities stem from incorrect or inadequate fan selection. Unexpected downtime on the production line, poor performance in filtration systems, increased energy consumption, or recurring maintenance problems are often caused not by the fan itself, but by its failure to be selected appropriately for the process.

In selecting the appropriate radial fan for the process, numerous technical parameters such as flow rate requirement, static pressure, ambient temperature, the composition of the gas being transported, and the operating regime of the facility directly influence the determination of the correct fan. A common situation encountered in the field is that selections made solely based on catalogue values significantly increase operating costs in the long term.

In this article, we will discuss the criteria for selecting high-efficiency industrial radial fans from an engineering perspective and based on practical application experience. Our goal is to provide technical teams with a clear and actionable roadmap for the decision-making process.

This article may interest you. Engineering, Design, and Optimization in Industrial Fan Manufacturing

What is an Industrial Radial Fan, and Where is it Used?

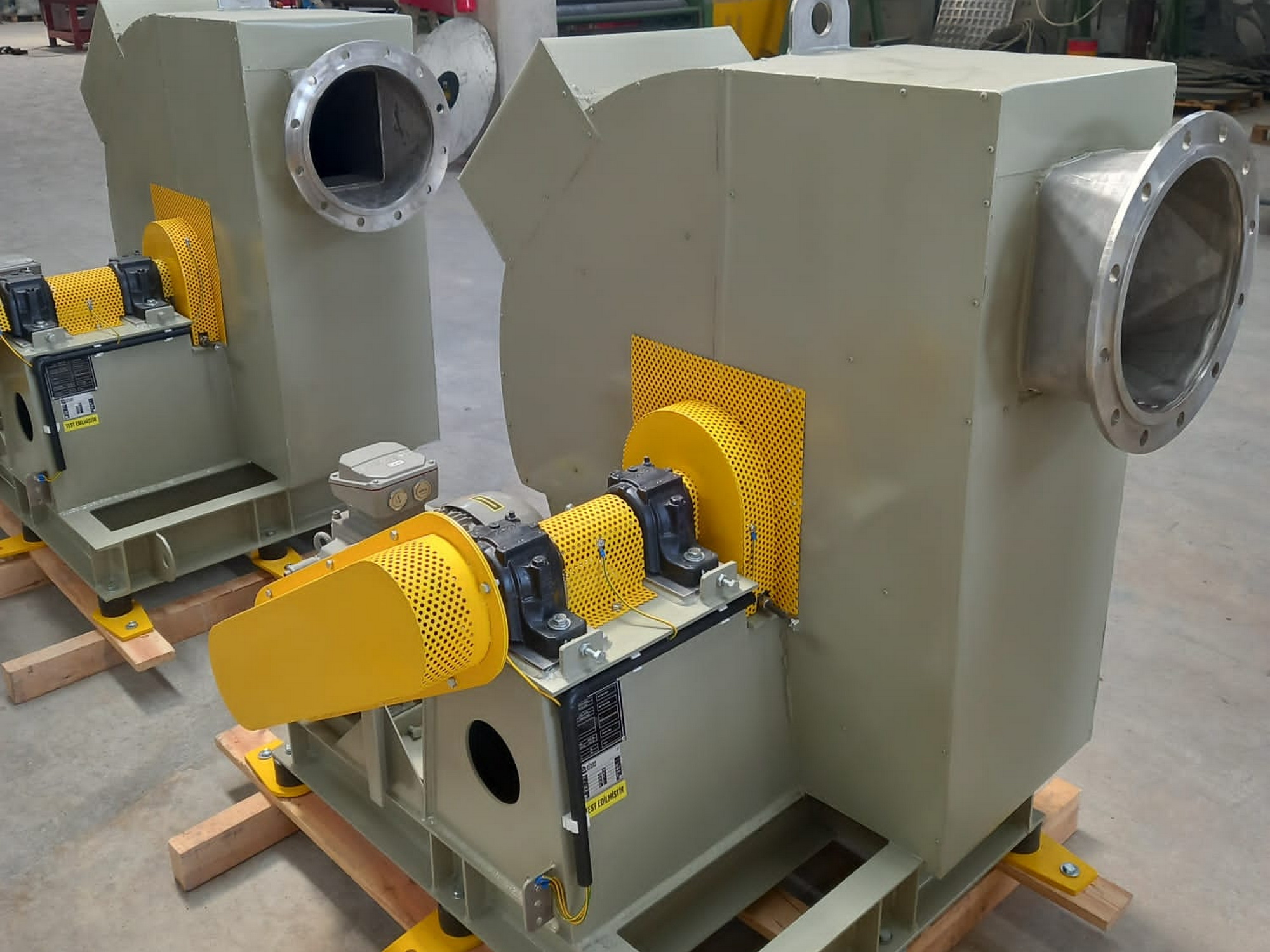

An industrial radial fan is a type of fan that draws air in from the center and expels it outward using centrifugal force, providing stable and controlled airflow in processes requiring high pressure.

Industrial radial fans draw air or gas into the center of the fan wheel and accelerate it toward the outer perimeter via the blades. Thanks to this working principle, they offer much more stable performance compared to axial fans, especially in systems that require high static pressure. This is also the main reason why they are preferred in applications where dusty, dirty, or hot gases are transported.

According to industry standards, radial fans are used in facilities where filtration resistance is high, long duct lines are present, or process equipment causes significant pressure loss. A common situation encountered in the field is that when switching to a radial fan in applications where an axial fan is insufficient, the system is seen to operate more stably and maintenance intervals are extended.

The main areas of application are as follows:

- Industrial dust collection and filtration systems

- Furnaces, drying, and thermal processing lines

- Paint shops and ventilation systems

- Chemical, cement, and metal processing plants

- Process exhausts requiring high pressure

In these types of applications, the radial fan does more than just move air; it becomes critical equipment that directly affects process continuity, product quality, and energy efficiency.

How to Determine the Right Industrial Radial Fan for Your Process?

The selection of the right industrial radial fan for your process is made by evaluating flow rate, static pressure, temperature, gas composition, and operating continuity together; the correct result cannot be obtained by looking at a single parameter.

Selecting an industrial radial fan is often a more complex engineering problem than commonly believed. This is because the fan is not a standalone piece of equipment; it is part of a whole, together with the duct system, filters, process machines, and environmental conditions. Therefore, simply asking “how many m³/h of air does it push?” is not sufficient during the selection phase.

A common situation encountered in the field is that even when the flow rate requirement is calculated correctly, the fan fails to deliver the expected performance in systems where static pressure losses are ignored. Long duct lines, elbows, dampers, and filter systems, in particular, significantly increase the total pressure loss. This leads to a fan that appears sufficient in theory but proves inadequate in practice.

The key parameters that must be evaluated together for correct fan selection are as follows:

- Flow requirement (m³/h): The amount of air required by the process

- Static pressure (Pa): Total resistance caused by ducts, filters, and equipment

- Ambient temperature: Directly affects fan material and motor selection

- Composition of the transported gas: Dusty, humid, or chemically-laden fluids

- Operating regime: Continuous or intermittent operation

As commonly seen in production processes, if one of these parameters is incorrectly evaluated, the fan will either consume more energy than necessary or begin to exhibit mechanical problems in a short time. At this point, engineering calculations and field data become much more decisive than catalog information.

What Does High Efficiency Mean? (Not Just the Motor)

High efficiency in industrial radial fans is achieved not only by motor efficiency, but also by optimizing the impeller geometry, casing design, sealing, and correct operating point together.

In industry, when we talk about “high-efficiency fans,” the focus is often solely on the motor class. In practice, however, the total efficiency of the fan is a much broader engineering whole than just the electrical efficiency of the motor. The blade angle, diameter, and surface quality of the impeller; the design of the casing to reduce flow losses; and the sealing details determine the actual performance of the fan.

A reality we have observed in practice for years is that a fan equipped with a high-efficiency motor but with incorrect impeller geometry can lag behind a fan with a theoretically “weaker” motor but with the correct design. This is because when the fan operates outside its design point, both energy consumption increases and vibration and noise problems arise.

According to industry standards, high efficiency is achieved by operating the fan as close as possible to its most efficient operating point (BEP – Best Efficiency Point). Therefore, when selecting a fan, it is necessary to focus not only on the maximum flow rate value, but also on

- Not only to the maximum flow rate value,

- But to the actual operating point on the operating curve,

- Long-term energy consumption

A properly designed industrial radial fan can provide energy savings far greater than the initial investment cost over its operational lifetime.

The 5 Most Critical Technical Criteria in Industrial Radial Fan Selection

For the right result in industrial radial fan selection, flow rate–pressure balance, environmental conditions, material selection, vibration quality, and energy consumption must be evaluated together.

Although industrial radial fans are presented with similar technical data, there are some critical engineering criteria that determine their performance. Neglecting any of these criteria can lead to the fan becoming inefficient in a short time or failing earlier than expected.

The 5 most critical technical criteria

- Flow rate and static pressure balance:The amount of air the fan will provide and the total pressure loss of the system must be considered together. A high flow rate value alone does not mean sufficient performance.

- Ambient temperature and process conditions:High temperatures directly affect the fan casing, impeller material, and motor selection. Incorrect material selection can cause deformation and balance problems.

- Material selection (casing and impeller):In environments containing dust, abrasive or chemical gases, stainless steel or special alloys may be required instead of carbon steel.

- Vibration and balance quality:As a common situation in the field, insufficiently balanced fans significantly shorten bearing life and increase maintenance costs.

- Energy consumption and operating cost:A fan with a low initial investment cost may increase the total cost in the long run due to high energy consumption. Therefore, the life cycle cost must be considered.

According to generally accepted practices, when these five criteria are evaluated together, it ensures that the fan not only operates but also operates sustainably and reliably. Choices made from an engineering perspective create a significant long-term advantage for businesses.

Usage Scenarios According to Radial Fan Types

Radial fan types offer different pressure, efficiency, and dirty air resistance depending on the blade geometry. Choosing the right type determines the fan’s suitability for the process conditions.

Industrial radial fans are not limited to a single standard design. The blade structure of the fan impeller directly affects how efficiently and safely the fan will operate in a given application. As we have seen in practice over the years, selecting the right fan type reduces both energy consumption and maintenance requirements significantly.

The table below summarizes the most common radial fan types and typical usage scenarios in a straightforward manner:

| Radial Fan Type | Pressure Level | Efficiency Characteristics | Typical Applications |

|---|---|---|---|

| Backward Curved Blades | Medium – High | High efficiency, stable operation | Filtration systems, process ventilation, industrial exhaust |

| Forward Curved Blades | Low – Medium | High airflow at low pressure | HVAC applications, clean air ventilation systems |

| Radial (Straight) Blades | High | High resistance to dust and particles | Dust-laden, abrasive and heavy-duty industrial processes |

According to industry standards, backward-curved blade fans are preferred in applications where energy efficiency is a priority, while straight-bladed radial fans stand out for their reliability in processes with high dust loads. Forward-curved blade fans are generally used in low-pressure and clean air applications.

The critical point here is not to select the “most powerful” or “highest flow rate” fan, but to determine the fan type that best suits the operating characteristics required by the process. Otherwise, the fan will not perform as expected, operating outside its design purpose.

Most Common Mistakes Made During the Design Phase

The most common mistakes in industrial radial fan projects are selecting fans from catalogs, incomplete pressure calculations, and ignoring field conditions.

In industrial facilities, fan systems often remain in the background of the project process. However, in practice, an incorrectly designed fan system can negatively affect the efficiency of the entire process. The most common mistake we have seen in practice over the years is selecting fans based solely on catalog data.

A common situation encountered in the field is that fans selected during the design phase without taking actual pressure losses into account fail to achieve the targeted flow rate after commissioning. Duct lengths, elbow counts, filters, and process equipment are often not fully reflected in the calculations. This causes the fan to operate continuously under strain and leads to early mechanical problems.

The most common design errors can be summarized under the following headings:

- Failure to conduct a site survey: Actual operating conditions are ignored

- Failure to account for future capacity increases: The system quickly becomes inadequate

- Failure to evaluate the characteristics of the gas to be transported and the environmental conditions: If the catalogue values are not evaluated together with the environmental conditions in which the fan will operate (process pressure, ambient altitude, process temperatures, etc.), an inefficient fan with high energy consumption or one that cannot deliver the gas required for the process will be selected.

- Neglecting vibration and noise factors: Occupational safety and comfort issues arise

- Failure to consider service and maintenance access: Operating costs increase in the long term

According to generally accepted practices, a successful fan project involves not only the right fan, but also the right placement, the right connections, and the right operating scenario. Therefore, the design phase is as critical an engineering process as the fan itself.

When is a Custom Design Required for Industrial Radial Fans?

Standard industrial radial fans become inadequate when process conditions exceed catalog values; at this point, a custom design becomes essential for performance and operational safety.

In industrial applications, no process exactly matches the “standard” conditions defined in the catalog. When dealing with high temperatures, corrosive or dust-laden gases, variable flow requirements, or limited installation space, standard radial fan solutions often fail to deliver adequate performance. This is where custom-designed fans come into play.

Our years of field experience have shown us that while a standard fan may appear to work in the short term, it increases operating costs in the long term due to increased energy consumption, balance problems, and frequent maintenance requirements. Custom-designed radial fans, on the other hand, are sized according to the actual needs of the process, ensuring that the fan remains stable at its most efficient operating point for a long time.

Efsan Makina addresses this need in industrial radial fan projects not only on a product basis but also as an engineering process. Recognizing that fan selection without analyzing process conditions will not yield healthy results, flow rate, static pressure, temperature, gas composition, and plant layout are evaluated together. This approach aims not only for the fan to work but to work reliably for many years.

Typical situations where custom design is required include:

- High pressure or temperature requirements that standard fans cannot meet

- Abrasive and dense particulate gas flows

- Systems with variable flow requirements depending on the process

- Facilities requiring compact or special layout due to space constraints

As commonly seen in production processes, a specially designed industrial radial fan in such applications provides significant advantages not only in terms of performance but also in energy efficiency, ease of maintenance, and process continuity. Therefore, the fan should be considered not as a catalog product but as an integral part of the process.

The Right Radial Fan Directly Determines Process Performance

Industrial radial fan selection is not merely an equipment choice; it is a strategic decision that directly affects production continuity, energy efficiency, and maintenance costs. In systems where flow and pressure values are not calculated correctly and process conditions are not sufficiently analyzed, fans quickly begin to operate inefficiently. This translates into unexpected downtime and increased costs for businesses.

The clearest fact we have observed in practice over the years is this: An industrial radial fan that is appropriately selected and correctly designed for the process pays back much more than the initial investment cost in the long term. Therefore, the fan should not be considered as a standard product selected from a catalog, but as an engineering solution tailored to the needs of the facility.

At this point, Efsan Makina stands out with its engineering-based approach to industrial radial fan projects. This approach, which focuses on process data, aims not only for the fan to work, but to work stably, safely, and efficiently for a long time. With the right fan selection, it is possible to make production performance sustainable.

For your industrial radial fan needs, contact Efsan Makina for engineering solutions tailored to your process. Let’s determine the right fan for your technical team together.

tags :

More about the sector and our business