Table of Contents

- What is Ex-Proof?

- Why Use Ex-Proof Fan Systems?

- Basic Operating Principle of Ex-Proof Fan Systems

- Types of Ex-Proof Fans According to Application Areas

- Criteria to Consider When Selecting Ex-Proof Fans

- Explosion-Proof Fan Installation and Maintenance Processes

- Comparative Advantages of Ex-Proof Fans

- Innovative Technologies and Automation in Ex-Proof Fans

- Common Problems and Suggested Solutions

- The Future of Ex-Proof Systems: Sustainability and Digitalization

- Conclusion

Safety is not a luxury but a necessity in environments with explosion risks. In such areas, even the smallest spark or excessive heat can turn into a major disaster. This is where Ex-Proof fan systems, i.e., explosion-proof fans, come into play.

Ex-Proof technology encompasses special systems developed to ensure the safety of workers and facilities, particularly in industrial areas where flammable substances such as gas, dust, or vapor are present. Unlike ordinary fans, these systems are equipped with special enclosures.

Every part, from electrical connections to motor components, is designed to prevent sparks. This is because in such environments, not only high temperatures but also an electrical spark can lead to disaster. For this reason, Ex-Proof systems not only provide ventilation but also help maintain stability in hazardous environments.

Ex-Proof fans must have international certifications such as ATEX and IECEx. These certificates document that the product has passed specific tests and can be used safely in environments with explosion risks. Moreover, these fans are frequently preferred not only in industry but also in agriculture, food processing, and even some laboratory environments.

In short, Ex-Proof fan systems are not just functional equipment, but also a critical safety tool that protects human life and the production process. In the rest of this article, we will cover every detail, from what Ex-Proof systems are and how they work, to where they are used and how they should be selected.

What is Ex-Proof?

Definition of the Ex-Proof Concept

Ex-Proof is an abbreviation of the English term “Explosion Proof” and directly translates to “explosion-resistant.” However, when we delve into the technical aspect, Ex-Proof refers to devices and equipment that are not only resistant but also designed in such a way that they will not cause an explosion. The purpose of these systems is to prevent electrical equipment operating in environments containing hazardous gases or dust from becoming a potential ignition source.

The motors, connections, and all other components used in Ex-Proof fan systems are engineered to prevent sparking, overheating, and contact with explosive gases in the external environment. The electrical parts inside the fan are completely insulated and enclosed in special housings. This ensures that even in the event of a malfunction, no danger is spread to the external environment.

In industrial safety, such solutions are not optional but are mandated by regulations. Standards such as ATEX in Europe and NEC in the USA determine which equipment can be classified as Ex-Proof. A fan system that is not manufactured according to these standards cannot be used in explosive environments.

The concept of Ex-Proof is not limited to fans. Many other pieces of equipment, such as lamps, switches, sockets, and sensors, are also manufactured as Ex-Proof. However, fan systems play a much more critical role because they operate continuously and directly affect the ambient air.

Classification of Explosive Atmospheres

In environments where explosions may occur, these environments are divided into specific classes to accurately analyze the risk level. This classification is vital for determining the type and characteristics of the equipment to be used. According to European standards, this classification is generally carried out in accordance with the ATEX (Atmosphères Explosibles) directive. According to ATEX, explosive atmospheres are divided into two main groups:

- Group I: For underground environments such as mines.

- Group II: All other industrial environments (chemical, petroleum, paint, food, etc.).

These are further subdivided as follows:

- Zone 0: Areas where explosive gas atmospheres are present continuously.

- Zone 1: Areas where explosive gas atmospheres may occur during normal operation.

- Zone 2: Areas where explosive gases are present only rarely and for short periods.

Similarly, dusty environments are classified as Zone 20, Zone 21, and Zone 22. These classes play a decisive role in the selection of Ex-Proof equipment. For example, a fan to be used in a high-risk environment such as Zone 0 must be highly insulated and protected.

These classifications are a critical guide not only for manufacturers but also for engineers and occupational health and safety experts. Choosing a fan without knowing which class it belongs to can put both human life and the integrity of the facility at risk.

Why Use Ex-Proof Fan Systems?

Importance in Terms of Safety

Perhaps the greatest advantage of Ex-Proof fan systems is that they guarantee safety even in high-risk environments. In places where explosive gases, vapors, or dust are present, the use of ordinary electrical equipment can have serious consequences. This is where Ex-Proof technology comes into play.

These fans completely prevent sparks that could occur due to possible electrical faults or mechanical friction. Thanks to their special enclosures, they limit the passage between internal and external air and prevent the external environment from coming into contact with the internal electrical components. In addition, these fans have automatic shutdown systems in case of possible overheating. In other words, they are not only safe but also smart.

Beyond that, they meet workplace safety standards by minimizing the risks employees may be exposed to. In Turkey and around the world, many legal regulations mandate the use of such Ex-Proof systems in environments with explosion risks. Otherwise, violations could result in both financial penalties and, worse, loss of life.

Role in Preventing Industrial Accidents

According to statistics, a significant portion of industrial accidents stem from the use of inappropriate equipment. In particular, most fires and explosions in environments containing chemical gases occur due to spark-producing devices. In such situations, Ex-Proof fan systems come into play, acting as a “protective shield.”

Ex-Proof fans not only exhaust air but also prevent the accumulation of hazardous gases in the environment. This significantly reduces the risk of explosion. Additionally, some models feature integrated systems such as gas detectors and temperature sensors. These systems automatically activate when they detect a hazardous change in the environment and stabilize the conditions.

Today, many large industrial facilities have made the use of Ex-Proof equipment mandatory, learning from past experiences. This is because a single accident can result in millions of dollars in damage and irreparable losses. Therefore, making a preventive safety investment is much more profitable, both economically and humanely.

Basic Operating Principle of Ex-Proof Fan Systems

Explosion-Proof Construction Features

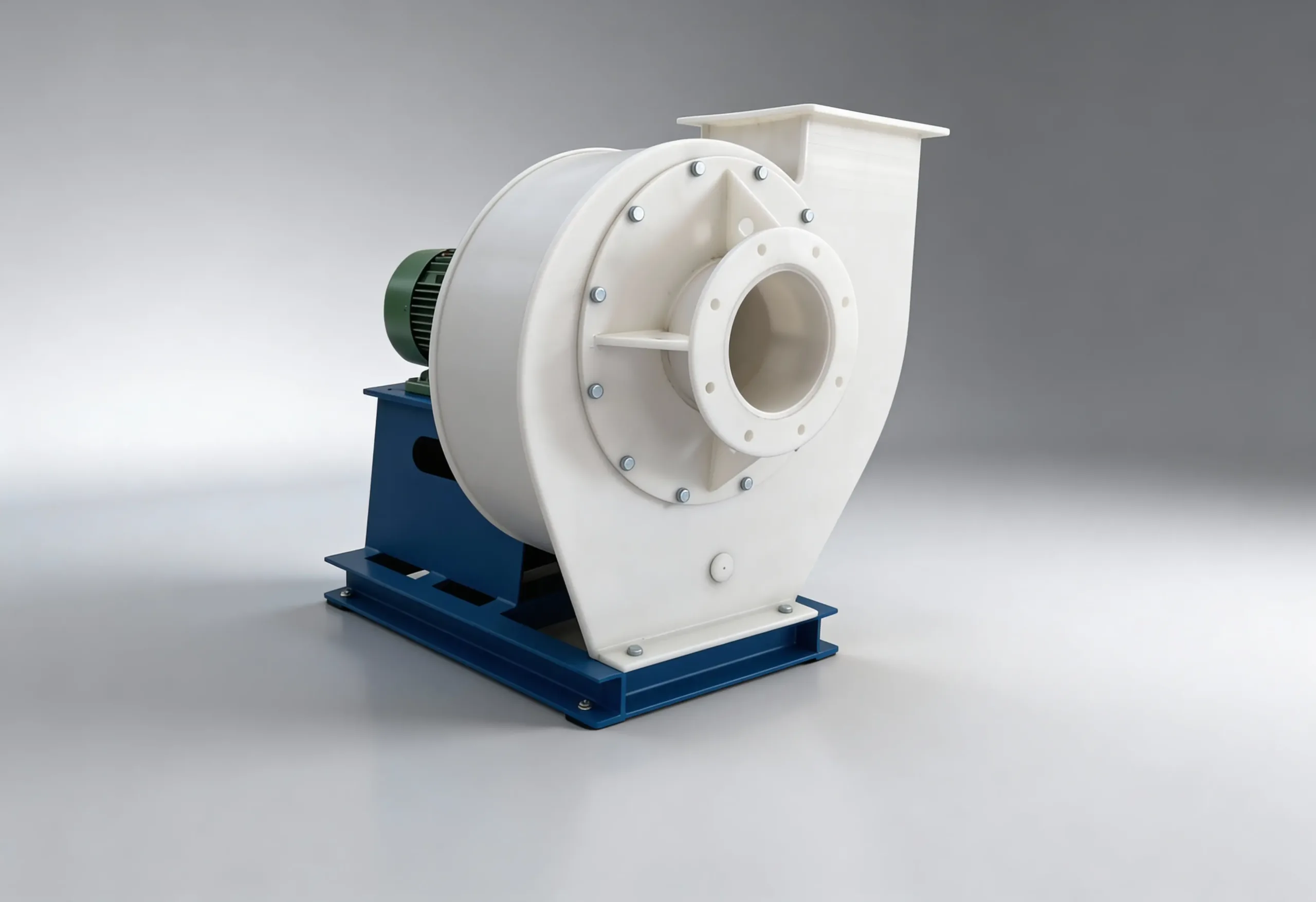

The most fundamental feature of Ex-Proof fan systems is that they are designed to prevent sparks, heat, or flames from escaping to the outside even in the event of an explosion. The motors, housings, cables, and connection points used in these systems are made of special alloys and are enclosed in a way that prevents contact with the external environment. Thus, even if a malfunction occurs inside, there is no risk of an explosion.

The housing of these fans is usually made of stainless steel, cast aluminum, or copper alloy metal. These materials are both heat-resistant and stand out for their non-sparking properties. In addition, the blades are coated with materials that prevent static electricity buildup. The exterior of the motor is housed in a completely enclosed box, which eliminates any interaction between the motor and the external environment.

Furthermore, the bearings used in fan systems minimize friction, reducing heat generation. In addition, some systems feature special cooling systems. This ensures that the fan does not overheat even when operating for long periods, eliminating the risk of explosion.

In short, every part of Ex-Proof fans—from the propeller to the motor, from the bearings to the cable entries—is made of carefully selected materials that have undergone special testing. This ensures that the fans are not only explosion-proof but also durable and safe.

Air Flow Control and Risk Management

Another critical aspect of Ex-Proof fan systems is that they prevent the accumulation of hazardous gases or vapors by directing the ambient airflow correctly. This is because these gases usually settle on the floor or accumulate on the ceiling; if not properly vented, they pose a danger. At this point, the fans ensure that the air remains in constant motion and that hazardous areas are ventilated.

The correct positioning of fans is also very important. They are usually placed at low levels and ceiling voids where explosive gases can accumulate. This ensures maximum safety by targeting the points where gases concentrate. Ex-proof fans can be programmed to automatically activate when the gas concentration in the environment increases. This saves energy and prevents danger without the need for human intervention.

Furthermore, in some systems, the environment is analyzed using integrated sensors. If the level of hazardous gas exceeds a certain limit, the system automatically sounds an alarm or speeds up the fan to quickly clear the environment. This demonstrates that fan systems can be used not only as ventilation devices but also as risk management tools.

It should be remembered that poor ventilation not only increases the risk of explosion but also threatens the health of workers. Prolonged exposure to toxic gases can cause dizziness, respiratory problems, and more serious health issues. Ex-Proof fan systems protect both workplace safety and worker health.

Types of Ex-Proof Fans According to Application Areas

Chemical Industry Applications

The chemical industry is one of the areas where Ex-Proof fan systems are used most intensively. This is because various flammable, explosive, or toxic gases are constantly processed here. Substances mixed into the air during processes such as the vaporization of liquids, gas reactions, and chemical reactions can cause a massive explosion at the slightest spark.

Ex-proof fans used in such environments both stabilize the ambient air and instantly evacuate gas leaks. These fans are indispensable in areas such as reactor rooms, laboratories, and production lines. Fans are designed to operate 24/7, especially in facilities that use solvent-based production. This is because solvents are highly volatile substances and pose a serious risk when suspended in the air.

Furthermore, these fans used in the chemical industry must generally be resistant to corrosive environments. This is because some chemicals can corrode ordinary metal surfaces over time. For this reason, stainless steel, PTFE coating, or special chemical-resistant alloys are preferred in Ex-Proof fans.

Finally, fans in chemical plants are usually controlled through a central system. Thus, when a hazard is detected, the system automatically activates and provides the necessary ventilation. This eliminates human error and creates an extra layer of safety.

Use in Oil and Gas Facilities

Oil refineries, natural gas processing plants, fuel storage areas… In such places, the risk of explosion is almost ever-present. Therefore, it is virtually mandatory that all equipment used in these industries be Ex-Proof. Fan systems are also one of the most critical links in this safety chain.

In the oil and gas industry, there are many processes where gases are transported through pipes or processed in open areas. In these processes, even the smallest gas leak can cause a major explosion when it comes into contact with a spark. That is why Ex-Proof fans are installed, especially in areas where gas accumulation is possible, and provide continuous ventilation.

Furthermore, fans used in offshore structures such as oil platforms must be resistant not only to explosions but also to salt water and moisture. For this reason, marine-grade stainless steel materials and extra insulation systems are preferred in these fans. In addition, since Zone 0 or Zone 1 environments are commonly found in these areas, fans with the highest level of protection must be used.

Fan systems used in the oil and gas industry are usually integrated into SCADA systems. This allows for remote monitoring and immediate intervention. This increases the safety of workers in the field and prevents potential malfunctions.

Food Industry and Agricultural Areas

Did you know that Ex-Proof fans are used not only in heavy industrial areas but also in the food and agriculture sectors? Yes, especially in places such as flour mills, feed production facilities, and grain silos, fine dust suspended in the air poses a serious explosion risk. Dust explosions are as dangerous as chemical explosions and are often overlooked.

Ex-proof fan systems used in these types of areas continuously remove dust particles from the environment and prevent the air from becoming stagnant. Substances such as flour, starch, and corn dust become highly flammable when mixed with air, especially in enclosed spaces. Even a single static electricity discharge can cause a major disaster in such environments.

In agricultural storage areas, these fans ensure continuous air circulation within the silo. This prevents mold growth and disperses potential gas accumulations. Additionally, the fans must be stainless and dust-proof because hygiene is crucial in such environments.

Furthermore, fans used in the food industry must be certified for use on surfaces that do not come into contact with food. In other words, they must be both Ex-Proof and compliant with hygiene standards. This means that these fans must be manufactured to much higher standards.

Criteria to Consider When Selecting Ex-Proof Fans

Certifications and Standards

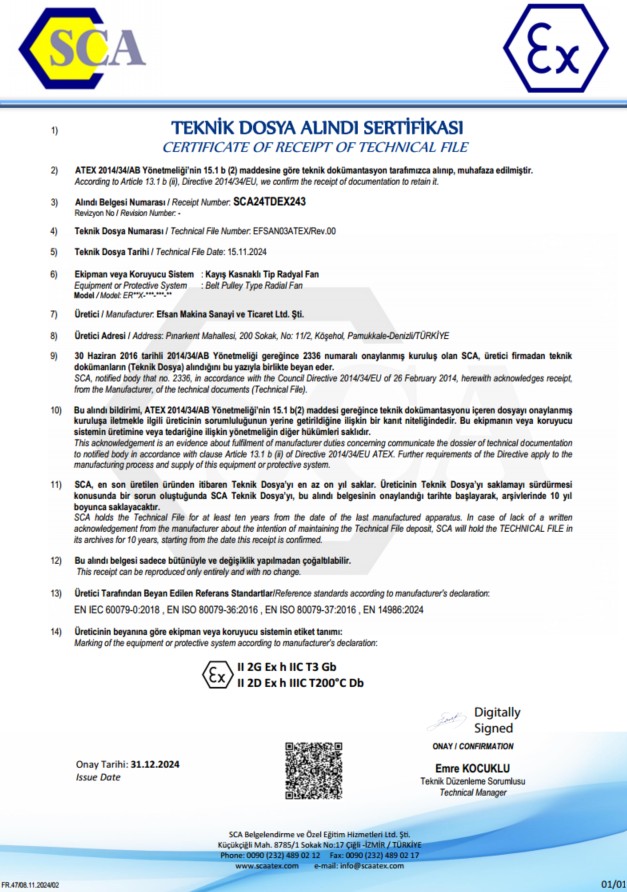

When selecting equipment of vital importance, such as Ex-Proof fan systems, the most fundamental factor to consider is the certifications they possess. This is because these certifications guarantee that the product has passed specific safety and performance tests and complies with legal regulations. The most common certification in the European Union is ATEX, while IECEx certifications are most common worldwide. The

ATEX (Atmosphères Explosibles) certification is a document issued under the 2014/34/EU directive and is mandatory for equipment to be used in explosive environments in Europe. The fan’s motor, electrical connections, structural materials, and design are tested in accordance with this directive. ATEX labels also indicate which Zone area the product is suitable for. For example, a fan to be used in Zone 1 must be tested and certified under these conditions.

IECEx (International Electrotechnical Commission Explosive Atmospheres) is an international standard and is also valid outside Europe. It is particularly important for companies operating globally. IECEx not only monitors the performance of Ex-Proof fans but also their production processes and quality management.

In addition, there are American-based certifications such as NEC (National Electrical Code), UL (Underwriters Laboratories), and FM (Factory Mutual). If the fan system is to be used in the US, it must comply with these standards.

Uncertified or counterfeit certified products pose serious safety risks. Moreover, they can expose companies to significant penalties not only in terms of safety but also legal liability. Therefore, when purchasing Ex-Proof fans, the validity, dates, and verification information of their certifications must be checked.

Material Quality and Structural Durability

It is not enough for an Ex-Proof fan system to be explosion-proof; it must also be durable, robust, and resistant to environmental factors for long-term use. Material quality plays a decisive role here. Fans operating in harsh industrial environments, in particular, must be highly resistant to dust, moisture, heat, and chemicals.

Stainless steel, aluminum casting, copper alloys, or anti-static plastic are commonly used as body materials. Stainless steel is widely used in the chemical and food industries due to its corrosion resistance and ease of cleaning. Aluminum is preferred for its lightness and conductivity.

Fan blades are also very important. These parts are usually coated with anti-static and non-sparking materials. Some special models use carbon fiber or special plastic composites. This provides extra safety, especially in environments where static electricity buildup is dangerous.

Additionally, attention must be paid to the physical conditions of the area where the fan will be installed. If it will be used in high-humidity environments, it should have a high IP rating. For example, the IP65 protection class provides complete protection against dust and low-pressure water. If the fan will be used in open areas, its resistance to UV rays and outdoor conditions should also be considered.

In short, when purchasing an Ex-Proof fan, it is not only important that it is explosion-proof, but also that it has a structure that can withstand all the challenges of its environment. This is because even the smallest wear or deformation can put the entire safety system at risk.

Energy Efficiency and Performance

Ex-Proof fan systems are an important investment not only in terms of safety but also in terms of energy efficiency. This is because these types of fans are usually designed to operate 24/7. Continuous operation naturally increases energy consumption. However, thanks to high-efficiency fan motors, this consumption can be minimized.

The motor class of fans is very important in terms of energy efficiency. Most motors used today have IE2, IE3, or higher efficiency classes. IE3 motors have become a standard, especially in line with energy regulations in Europe. These motors reduce operating costs and minimize environmental impact by providing more airflow with less energy.

Furthermore, having a speed control feature on the fan also increases energy savings. Ex-Proof fans equipped with frequency converters (VFD – Variable Frequency Drive), in particular, can adjust their speed as needed. When the gas or vapor density in the environment is low, the fan runs slower, and when the density increases, it speeds up. This both reduces energy consumption and extends the fan’s lifespan.

In terms of performance, there are several technical criteria to consider:

- Flow rate (m³/h): The amount of air the fan circulates per unit of time.

- Static pressure (Pa): The force with which the fan provides air flow.

- Rotation speed (RPM): The speed at which the fan blades rotate.

- Noise level (dB): The level of noise emitted during operation.

These values vary depending on the size of the environment in which the fan will be used, the gas density, and the duration of use. Careful analysis of these parameters is necessary to select the most suitable fan system.

Explosion-Proof Fan Installation and Maintenance Processes

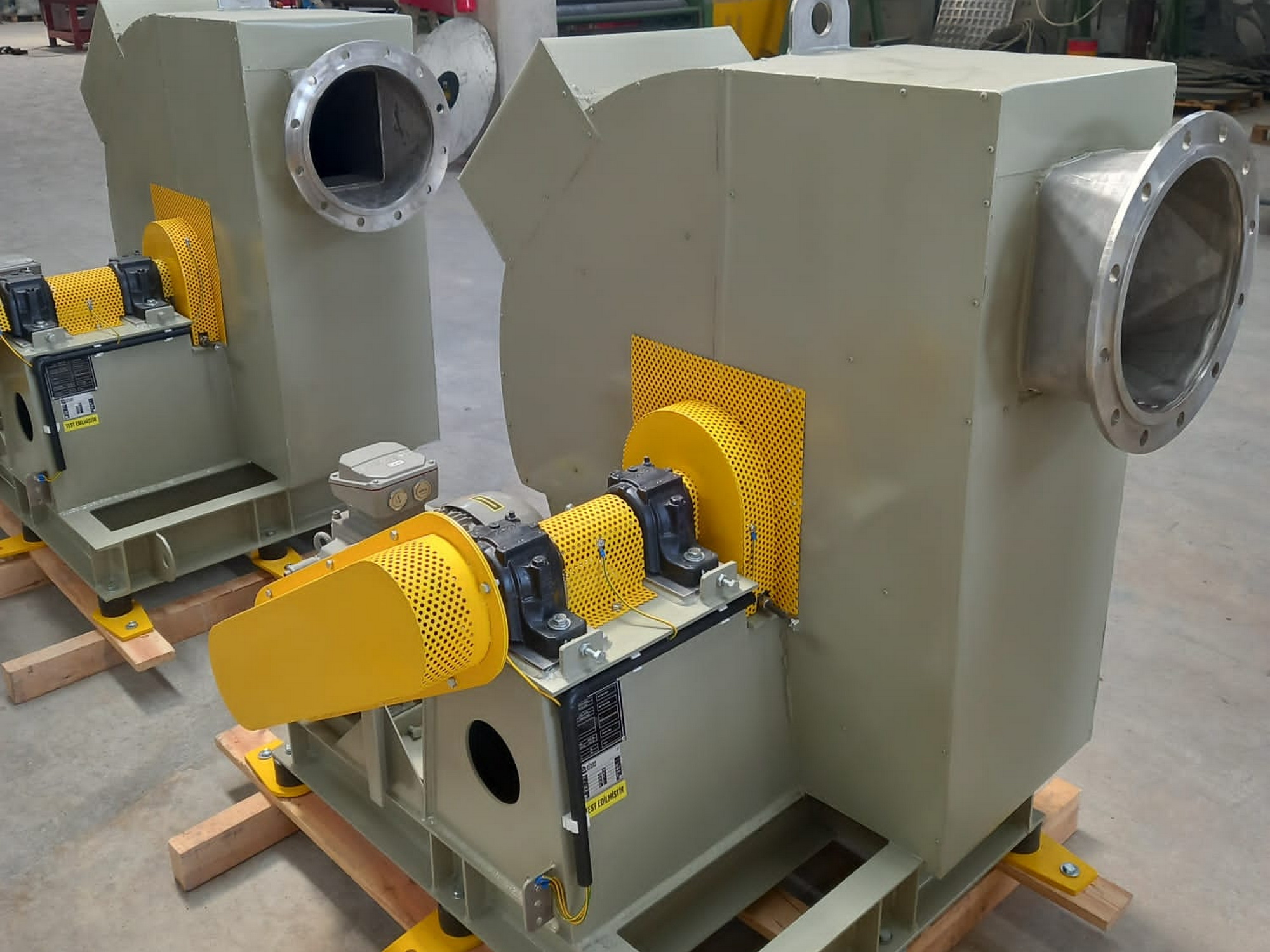

The installation and maintenance of explosion-proof fan systems is a much more delicate and careful process than that of ordinary fans. This is because the environments where these systems are located often contain explosive gases, vapors, or dust, and any incorrect procedure can lead to very serious consequences. Therefore, both installation and maintenance procedures should only be performed by authorized personnel who are specialized in this field.

The first point to consider during the installation process is the degree of suitability of the fan for the Zone area where it will be used. For example, the installation details for a fan to be used in Zone 1 may involve much stricter safety measures than those for Zone 2. In addition, before installation, it must be ensured that all electrical connections are closed and that there is no gas accumulation in the environment. Gas measuring devices are generally used during this process.

The location where the fan will be placed is also very important. Areas where air can circulate properly and where gas or dust accumulation is most likely to occur should be targeted. Furthermore, the fan must be secured so that it does not vibrate, cable connections must be leak-proof, and it must be integrated into the grounding system. Cable entries and boxes must be Ex-Proof and insulated to prevent sparking.

Maintenance should be performed periodically, and the environment should undergo gas analysis before each maintenance. The most common maintenance procedures are:

- Cleaning the fan blades (against dust and particle accumulation)

- Lubricating the motor bearings

- Checking the tightness and insulation of electrical connections

- Checking the sealing gaskets

- Checking for overheating and noise

Cleaning chemicals used during maintenance must also be Ex-Proof compliant; otherwise, there is a risk of reaction with the explosive environment. In addition, sensors, control panels, and automation systems integrated into the fan system must also be checked and updated in terms of software.

In short, the installation and maintenance of Ex-Proof fan systems is not only a technical process but also a safety procedure involving high risk. Therefore, detailed planning, expert personnel, and the use of the right equipment are essential.

Comparative Advantages of Ex-Proof Fans

When comparing Ex-Proof fan systems with other types of fans, the advantages they offer, especially in environments with explosion risks, are quite remarkable. These systems are not just a means of ventilation but also a vital safety measure. Here are some key advantages offered by Ex-Proof fans:

1. High Level of Safety

The biggest advantage is, of course, their resistance to explosions. While situations such as motor failure, cable short circuits, or overheating in ordinary fan systems can produce sparks, Ex-Proof fans eliminate these risks. This provides critical protection for both worker safety and the continuity of the facility.

2. Legal Compliance and Certification Ease

Ex-Proof fans, which have international certifications such as ATEX and IECEx, meet the legal standards required for equipment to be used in hazardous environments. This ensures that there are no problems during inspections, eliminates the risk of penalties for the facility, and results in high scores in occupational safety inspections.

3. Long Life and Durability

Ex-Proof fans are typically manufactured from high-quality, corrosion-resistant materials, allowing them to operate smoothly for long periods even in corrosive environments. This reduces maintenance costs and shortens the return on investment period.

4. Modular and Customizable Design

These systems are usually designed to be modular. Fan size, rotation speed, motor power, or material type can be selected according to need. Furthermore, their easy integration into automation systems provides remote monitoring and control capabilities.

5. Energy Efficiency

Thanks to high-efficiency motors, variable speed drives (VFD), and smart control systems, Ex-Proof fans can deliver more performance with less energy. This reduces operating costs while contributing to environmental sustainability.

6. Suitability for Different Industries

They can be used in a wide variety of sectors such as chemical, petroleum, mining, food, agriculture, pharmaceutical, paint, and textile. The fact that they can be customized according to the specific needs of each sector makes them a versatile solution.

These advantages of Ex-Proof fan systems position them not just as equipment, but as the key to safety. Therefore, it is essential for every business operating in high-risk environments to include these systems in their investment plans.

Innovative Technologies and Automation in Ex-Proof Fans

Today’s technology makes Ex-Proof fan systems not only safe but also “smart.” These fans no longer just exhaust air; they analyze the environment, instantly detect risks, and automatically take action when necessary. This transformation is made possible by the integration of Industry 4.0 into Ex-Proof systems.

Sensor Integration

Modern Ex-Proof fan systems can work in conjunction with temperature sensors, gas detectors, humidity sensors, and particle measurement devices. This allows the fan system to activate, increase its speed, or sound an alarm when it detects a hazard in the environment. This automation reduces risk without the need for human intervention.

Frequency Converter (VFD)

VFD systems integrated into fan motors provide energy efficiency by adjusting the motor speed as needed. This system operates according to the conditions of the environment, thus saving energy and extending the life of the equipment.

Integration with SCADA and BMS Systems

Ex-Proof fan systems can now be easily integrated into SCADA (Supervisory Control and Data Acquisition) or BMS (Building Management System) systems. This allows all fans to be monitored, controlled, and receive real-time status reports from a central panel. These systems provide management convenience, especially in large facilities.

Remote Monitoring and Fault Reporting

Internet-connected (IoT) Ex-Proof fan systems can be monitored remotely via a mobile phone or computer. In the event of a fault, the system automatically sends notifications to managers. This means quick intervention and minimal downtime.

Artificial Intelligence-Supported Control

Some advanced systems operate with artificial intelligence algorithms. These systems learn when the fan should be activated by analyzing historical data and optimize themselves over time. This ensures maximum safety and minimum energy consumption.

As a result, Ex-Proof fan systems have evolved beyond being merely a safety feature to become the digital brain of the facility. This technological transformation not only increases operational efficiency but also paves the way for a more sustainable, environmentally friendly production model.

Common Problems and Suggested Solutions

Although Ex-Proof fan systems are manufactured according to high safety and quality standards, encountering certain problems during use is inevitable. However, most of these problems can be prevented with proper maintenance, installation, and usage habits. Here are the most common problems and their solutions:

1. Overheating

One of the most common problems with Ex-Proof fans is overheating of the motor or bearings. This can be caused by factors such as overloading, incorrect voltage usage, or insufficient cooling or ventilation.

Solution: The fan’s operating load and motor power should be correctly calculated, the bearings should be lubricated periodically, and the electrical connections should be checked. In addition, temperature sensors should be operational and warnings should be heeded.

2. Low Performance / Insufficient Air Flow

If the environment is not sufficiently ventilated even though the fan is running, this is usually due to clogged blades, incorrect direction, or low motor speed.

Solution: Fan blades should be cleaned at regular intervals, filters should be checked, and the airflow channels should be positioned appropriately. If necessary, the fan speed should be increased using a frequency converter.

3. Vibration and Noise Problems

Excessive vibration or noise may be caused by the floor on which the fan is installed, imbalance, or a mechanical failure.

Solution: The fan should be installed correctly, vibration-preventing pads should be used, balance checks should be performed, and loose parts should be tightened.

4. Electrical Failures

Short circuits, blown fuses, or motor failure are usually caused by insufficient insulation, water or moisture leaks, or faulty wiring.

Solution: Cable connections must be Ex-Proof compliant, waterproof connection boxes must be used, cables must be grounded, and certified electrical materials must be preferred.

5. Use of Uncertified or Incorrect Products

Unfortunately, there are also counterfeit Ex-Proof fans on the market. Although these products may look similar from the outside, they have not undergone testing and approval processes.

Solution: When purchasing products, certificates must be checked, documentation verification must be requested from the manufacturer or distributor, and only reliable brands should be preferred.

In conclusion, many problems that can occur with Ex-Proof fans can be completely prevented with preventive maintenance and proper installation. In addition, training employees on the operating principles and risks of this equipment prevents potential hazards.

The Future of Ex-Proof Systems: Sustainability and Digitalization

With Industry 4.0, digitalization and sustainability in industrial systems are no longer just a preference but a necessity. Ex-Proof systems are also part of this transformation. In the future, Ex-Proof fan systems will not only provide safety; they will also become environmentally friendly, smart, and efficient production tools.

Energy Efficiency and Carbon Footprint

New generation Ex-Proof fans provide lower carbon emissions with low energy consumption. The developed IE4 and IE5 motors can operate up to 15% more efficiently compared to traditional motors. This both reduces the impact on the environment and lowers companies’ energy costs.

Smart Sensor Technologies

IoT (Internet of Things) technology will be at the forefront of future Ex-Proof systems. Each fan will analyze its own status, collect environmental data, and send real-time information to central systems. These systems will be able to independently perform tasks such as automatic notification in case of malfunction, energy consumption analysis, and air quality measurement.

Optimization with Artificial Intelligence

In some pilot projects, Ex-Proof fans operate with artificial intelligence-supported algorithms. The system analyzes historical data to learn when and how much it needs to operate and optimizes its own speed. This increases safety and extends device life by reducing wear and tear.

Renewable Energy Integration

Solar-powered fan systems have begun to be used, especially in silo and warehouse applications in open areas. In these systems, the fans run entirely on solar energy, minimizing energy requirements. This contributes to sustainability goals.

Environmentally Friendly Material Use

Future fan systems will be manufactured using recyclable and non-toxic materials. Low-emission technologies will also be used during production. This will reduce the environmental impact throughout the product’s entire life cycle.

In short, Ex-Proof systems are no longer just “explosion-proof”; they must also be “environmentally friendly, efficient, and smart.” Companies that keep pace with this transformation will increase not only safety but also their competitive strength.

Conclusion

Working in environments with explosion risks requires great care and responsibility. Every piece of equipment used in these environments takes on the task of protecting human life. Ex-Proof fan systems are one of the most important parts of this task. A properly selected, correctly installed, and regularly maintained Ex-Proof fan system not only provides ventilation; it also protects workers’ safety, keeps production processes running smoothly, and fulfills legal responsibilities.

Regardless of whether it is the chemical, petroleum, food, agriculture, or pharmaceutical industry, these systems, which are indispensable safety tools in hazardous environments, are equipped with the most advanced safety measures offered by technology. In the future, they will become even smarter with artificial intelligence, sustainable materials, and automation systems, further solidifying their place in the industry.

It should not be forgotten that safety is never a coincidence, but a conscious choice. Ex-Proof fan systems are the most reliable guarantee of this choice.

tags :

More about the sector and our business