Table of Contents

- Engineering Approaches in Industrial Fan Manufacturing

- Design and Performance Optimization in Industrial Fan Design

- Specialized Fan Engineering for Aggressive Environments, High Temperatures, and Demanding Process Conditions

- Process-Focused Solutions in Custom Radial Fan Production

- Sectoral Expertise, Project-Based Solutions, and High Engineering Power

- Conclusion: The Importance of Engineering and Optimization in Industrial Fan Production

Reliable air management in industrial facilities directly affects many critical parameters, from process efficiency to energy consumption, occupational safety to production quality. Therefore, industrial fan production is not just about creating a mechanical product; it is a highly specialized process that requires the simultaneous application of engineering, design, and optimization disciplines.

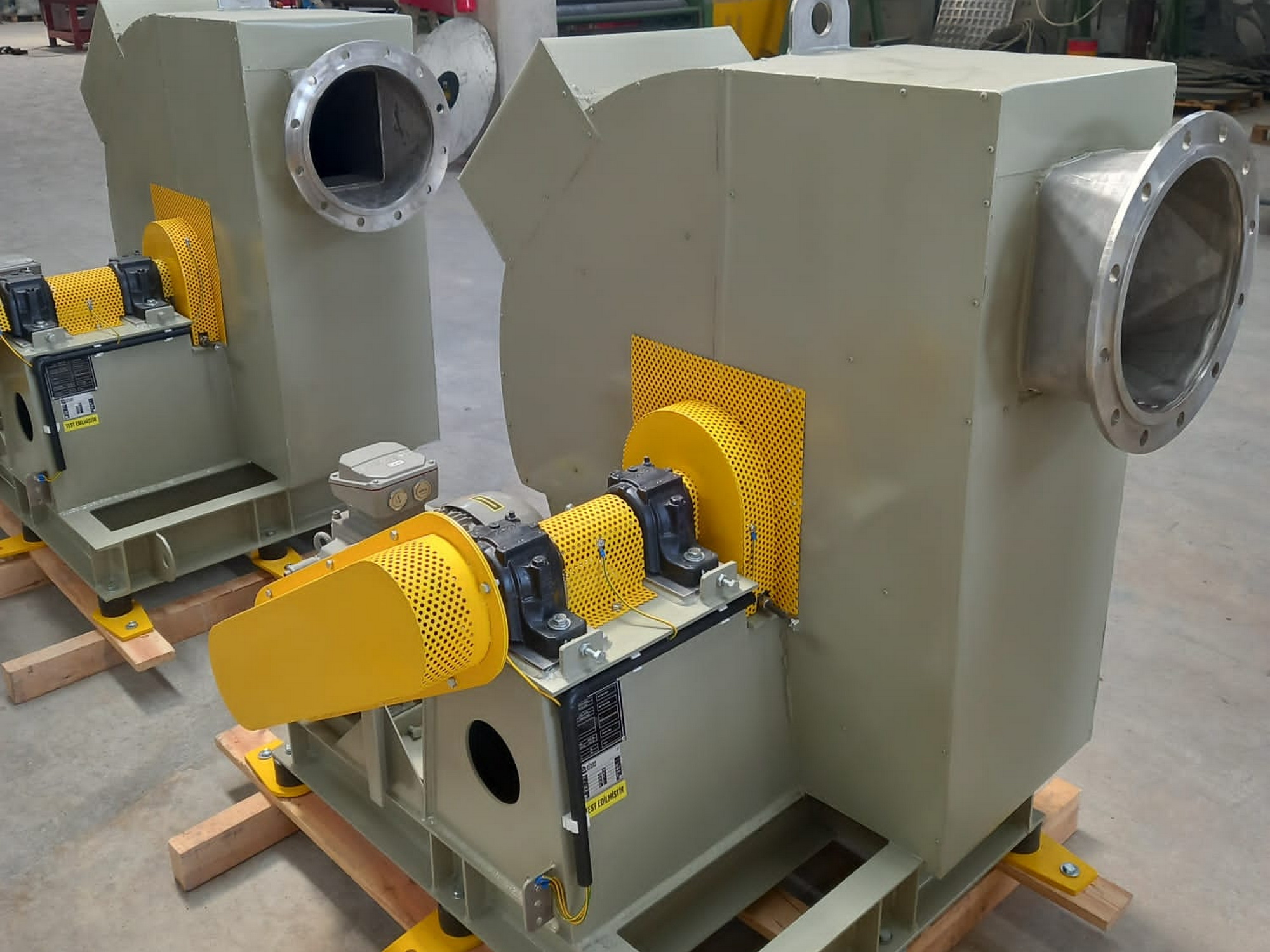

EFSAN, as a manufacturer that has been developing customized solutions for the needs of different sectors for many years, has strong references in a wide range of engineering, from pressurized and pressure-operated fan systems to ex-proof fans for hazardous environments and MVR (Mechanical Vapor Recompression) blower solutions for the chemical and food industries, to CCR (Continuous Catalyst Regeneration) projects in petrochemical plants.

In modern industry, where standard products are often insufficient, process requirements directly determine fan design. For this reason, EFSAN engineers perform aerodynamic analyses, material optimization, flow-pressure characteristics, and performance calculations tailored to the operating conditions for each project. In particular, custom radial fan production provides businesses with significant advantages in terms of high durability, energy efficiency, and long-term operation required by facilities.

In this article, we will address the engineering approach, design processes, and modern optimization techniques in industrial fan production from a concise, professional, and sector-specific perspective.

This article may interest you. How to Manufacture Industrial Fans Focused on Efficiency and Durability?

Engineering Approaches in Industrial Fan Manufacturing

Industrial fan manufacturing goes far beyond basic ventilation needs; it is an engineering discipline that combines fluid mechanics, materials science, vibration analysis, and mechanical strength calculations. Every detail, from the fan’s lifespan to its performance curves, is shaped by the right engineering approach.

The first step in this process is the accurate analysis of the process requirements of the facility where the fan will be used. Variables such as air flow rate, pressure loss, temperature, density changes, corrosive environments, or particle load determine the entire design process, from the fan’s body structure to the blade profile geometry.

Design and Performance Optimization in Industrial Fan Design

High performance in industrial fans is not achieved solely with a powerful motor or a durable casing. Every choice made during the design phase—blade angle, impeller diameter, casing geometry, material structure, and even surface roughness—directly affects the fan’s efficiency. Therefore, design is one of the most critical engineering steps in production.

Performance optimization proceeds simultaneously with the design phase. Thanks to modern analysis tools, vortex formation, flow errors, pressure fluctuations, and thermal effects can be simulated in advance to develop more efficient designs.

This approach plays a decisive role, especially in companies that produce special radial fans. This is because each project requires a different flow rate, pressure, temperature, or chemical resistance. Therefore, instead of standard solutions, optimized, highly precision-engineered fans both extend operational life and provide significant advantages in energy costs.

Specialized Fan Engineering for Aggressive Environments, High Temperatures, and Demanding Process Conditions

Industrial air management does not always take place under standard conditions. Many facilities feature chemically aggressive environments, saturated steam lines with high humidity, high-temperature zones ranging from 300–900°C, and process equipment operating at high speeds. Under these demanding conditions, a standard fan system cannot deliver long-term performance; it may even pose a risk to facility safety.

This is precisely where EFSAN stands out with its advanced engineering and specialized design capabilities. The company does not just produce standard products; it develops specially designed fan systems that are chemically resistant, utilize high-temperature-specific alloys, and are resistant to high pressure and high flow rates, by examining all the details of the process conditions.

In this context:

- Body-impeller structures with special coatings and corrosion resistance for aggressive chemical environments,

- High-efficiency MVR blower solutions unaffected by condensation in saturated steam applications,

- Designs with calculated thermal expansion tolerances and impeller-shaft-housing compatibility for high-temperature lines,

- dynamically balanced rotor systems with vibration optimization for processes requiring high speed and high pressure are developed, and each project is supported by engineering calculations.

Thanks to this approach, EFSAN offers industrial fan solutions that operate reliably under extreme conditions in many sectors such as chemical, petrochemical, energy production, food, metallurgy, textile, and mining.

Process-Focused Solutions in Custom Radial Fan Production

Custom radial fans play a critical role in processes requiring flow rate–pressure combinations, high temperatures, abrasive particle loads, or chemical resistance that standard products cannot meet. Therefore, the production process requires an engineering effort that starts from scratch for each project.

The basis of process-oriented design is the accurate analysis of the customer’s operational needs. At this stage, the environment and operating conditions to which the fan will be exposed are clearly defined:

- Temperature range

- Corrosive gases or particles

- Pressure losses

- Energy efficiency targets

- Constant or variable flow rate requirements

Based on this information, the fan body material, impeller design, blade type, bearing structure, and drive system are determined. Subsequently, precise balancing, vibration control, and endurance tests are performed during the production phase.

Thanks to this engineering approach, the custom radial fans produced contribute directly to the performance of businesses with high efficiency, low maintenance requirements, and long service life. These fans are an indispensable solution for the sustainability of operations, especially for facilities operating in heavy processes.

Sectoral Expertise, Project-Based Solutions, and High Engineering Power

Petrochemical, energy, chemical, and heavy industry facilities are sectors with the most challenging process conditions, such as high pressure, aggressive environments, high temperatures, and explosive atmospheres. Fan systems used in these areas play a critical role not only in terms of high performance but also in terms of safety, durability, and process efficiency.

EFSAN has become a strong reference point in the production of high-pressure fans, EX-Proof solutions, MVR blowers, and CCR blowers with its years of engineering experience in these demanding industries. Each project is custom-designed by examining plant conditions, process dynamics, pressure-flow requirements, and risk analyses.

The company’s key advantages:

- High engineering capacity with the ability to design for demanding processes

- Competitive cost structure, optimized production processes

- Fast service and technical support, an approach that minimizes critical plant downtime

- Project-based production approach, performance-focused solutions tailored to each plant

- Safety and quality practices compliant with international standards

In this respect, EFSAN is not just a manufacturer that supplies products; it is also an engineering solution partner that supports the efficiency, safety, and sustainability goals of industrial enterprises.

Conclusion: The Importance of Engineering and Optimization in Industrial Fan Production

Industrial fan production is not a simple mechanical manufacturing process; it is a multi-layered field of expertise where engineering, design, and optimization work together. A fan’s performance in operation depends on accurately calculated flow-pressure curves, optimized blade geometry, appropriate material selection, and precise manufacturing processes.

For this reason, modern industrial facilities now prefer radial fans designed specifically for process requirements, rather than just standard fan solutions. Thanks to their high efficiency and long service life, these fans reduce operating costs while also maximizing process safety.

As a result, a professional manufacturing approach that combines engineering disciplines both enhances fan performance and contributes to the sustainable and energy-efficient operation of facilities. Custom-designed radial fans stand out as one of the clearest outcomes of this holistic approach.

tags :

More about the sector and our business