Industrial fan systems are critical for process safety, energy efficiency, and production continuity in industrial facilities. The right choice of fan and technology directly affects not only airflow but also production costs and facility safety. Therefore, technical performance, energy consumption, maintenance costs, and investment payback period must be considered when selecting a fan. You can find a comprehensive guide to industrial fan types and their applications in this article

In this article, we discuss industrial fan types, including Radial Fans, MVR Systems, CCR Units, and Turbo Compressors, covering their technical aspects and applications.

Industrial Fan Types:

- Radial Fans (Centrifugal Fans)

- MVR (Mechanical Vapor Recompression)

- CCR Unit (Continuous Catalytic Reforming)

- Turbo Compressors

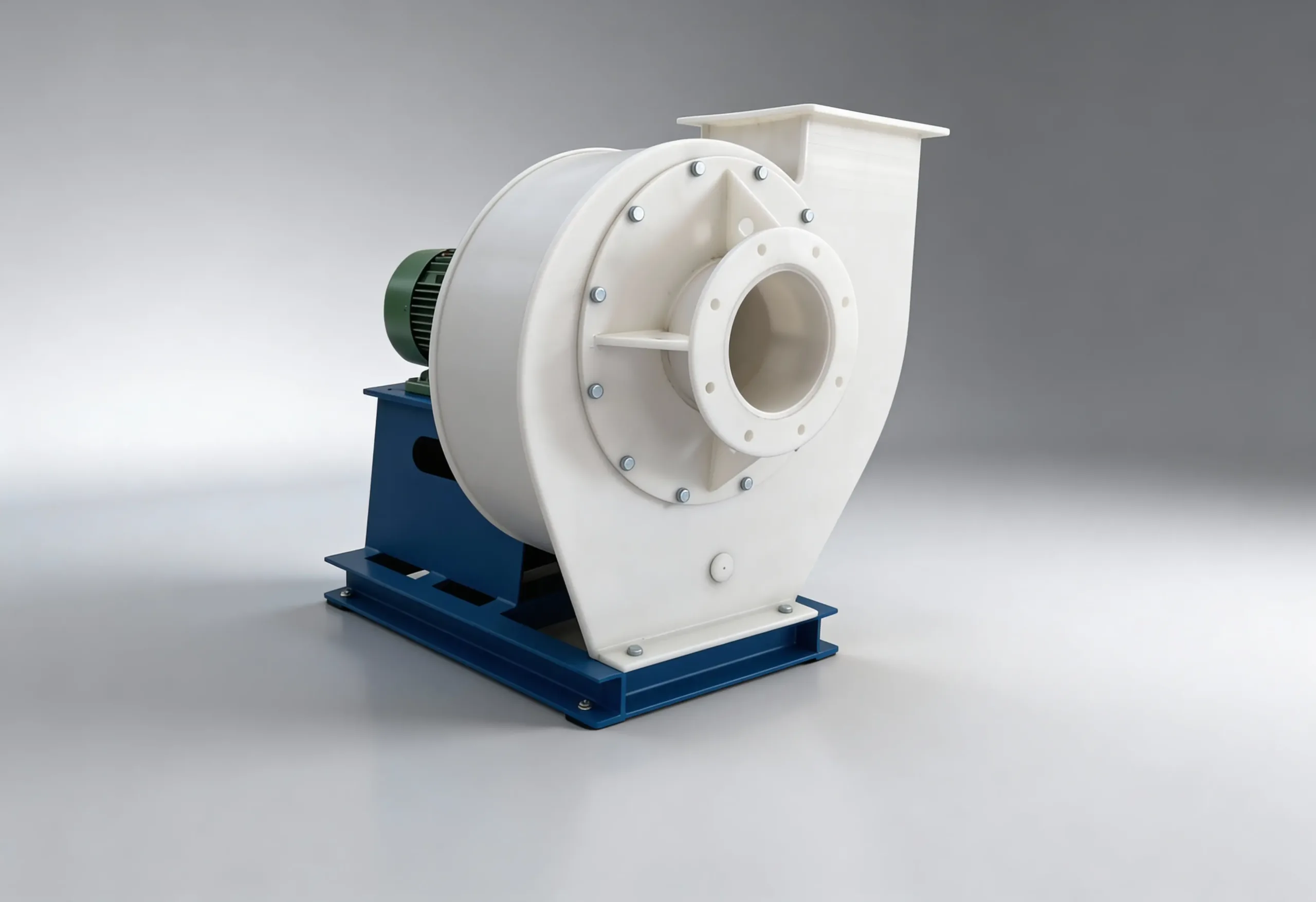

Radial Fans (Centrifugal Fans)

Working Principle:

Radial fans draw air from the center and discharge it outward at a 90° angle, providing controlled flow under high pressure. They stand out for their reliable performance in heavy industrial conditions.

Types and Applications:

- High-Pressure Radial Fans: Clinker cooling in cement plants, material transfer in pneumatic conveying systems.

- Sealed Radial Fans: Safe transportation of aggressive gases such as chlorine and ammonia in chemical plants.

- Ex-Proof (Explosion-Proof) Fans: Solvent vapor extraction in petrochemical plants, methane gas ventilation in mines.

When selecting fans for industrial investments, not only the initial investment cost but also maintenance expenses, energy consumption, and system lifespan should be evaluated. In this regard, Efsan Makina offers quality and performance at more affordable prices compared to other fan manufacturers in Turkey. With its competitive pricing policy, the company produces more economical solutions than its competitors, providing long-term advantages thanks to low maintenance costs, while also offering significant savings opportunities to businesses with its energy-efficient designs. With all these features, Efsan Makina is positioned as the company offering the highest quality and most affordable solutions among Turkey’s domestic industrial fan manufacturers.

MVR (Mechanical Vapor Recompression)

Working Principle:

Mechanically compresses industrial steam and makes it reusable.

Areas of Use:

- Food industry: Milk powder, coffee, fruit juice concentrate.

- Chemical industry: Solvent recovery, solution concentration.

- Wastewater management: Water recovery through evaporation.

Advantages

- Up to 90% energy savings compared to traditional evaporation.

- Low operating costs.

- Environmentally friendly production.

CCR Unit (Continuous Catalytic Reforming)

Working Principle

Converts low-octane naphtha into high-octane gasoline in petroleum refineries and also produces hydrogen.

Areas of Use:

- Energy sector: Production of high-quality gasoline.

- Chemical industry: Source of hydrogen for methanol, ammonia, and aromatic chemicals.

Advantages:

- High efficiency with continuous process.

- Improved product quality in refineries.

- Long-lasting catalyst technology.

Turbo Compressors

Working Principle:

Increases pressure and flow rate by compressing gases with high-speed rotating turbine blades. Belongs to the dynamic compressor group and is preferred in high-performance processes.

Areas of Use:

- Petrochemicals: Gas compression and transport of process gases.

- Power plants: Supply of feed air to gas turbines.

- Steel and metallurgy: Oxygen enrichment with high-pressure air.

- Wastewater treatment plants: Oxygen transfer in aeration tanks.

Advantages:

- High flow and pressure capacity.

- Energy efficiency.

- Low vibration and noise levels.

- Long-term uninterrupted operation.

Key Considerations for Selecting Industrial Fans and Systems

- Pressure and flow rate requirements must be calculated correctly.

- Environmental conditions (dust, temperature, gas) must be taken into account.

- Energy efficiency reduces long-term costs.

- Material selection must be based on the process.

- Service and spare parts support must be evaluated.

Efsan Makina: Reliable and Affordable Industrial Solutions

Efsan Makina, developed with local R&D and engineering power:

- Radial Fans (high pressure, leak-proof, ex-proof),

- MVR Systems,

- CCR Unit Technologies,

- Turbo Compressors

stands out among Turkey’s leading industrial fan manufacturers. While offering more affordable solutions than competing manufacturers, it provides businesses with high performance and cost advantages without compromising on quality and technology.

tags :

More about the sector and our business