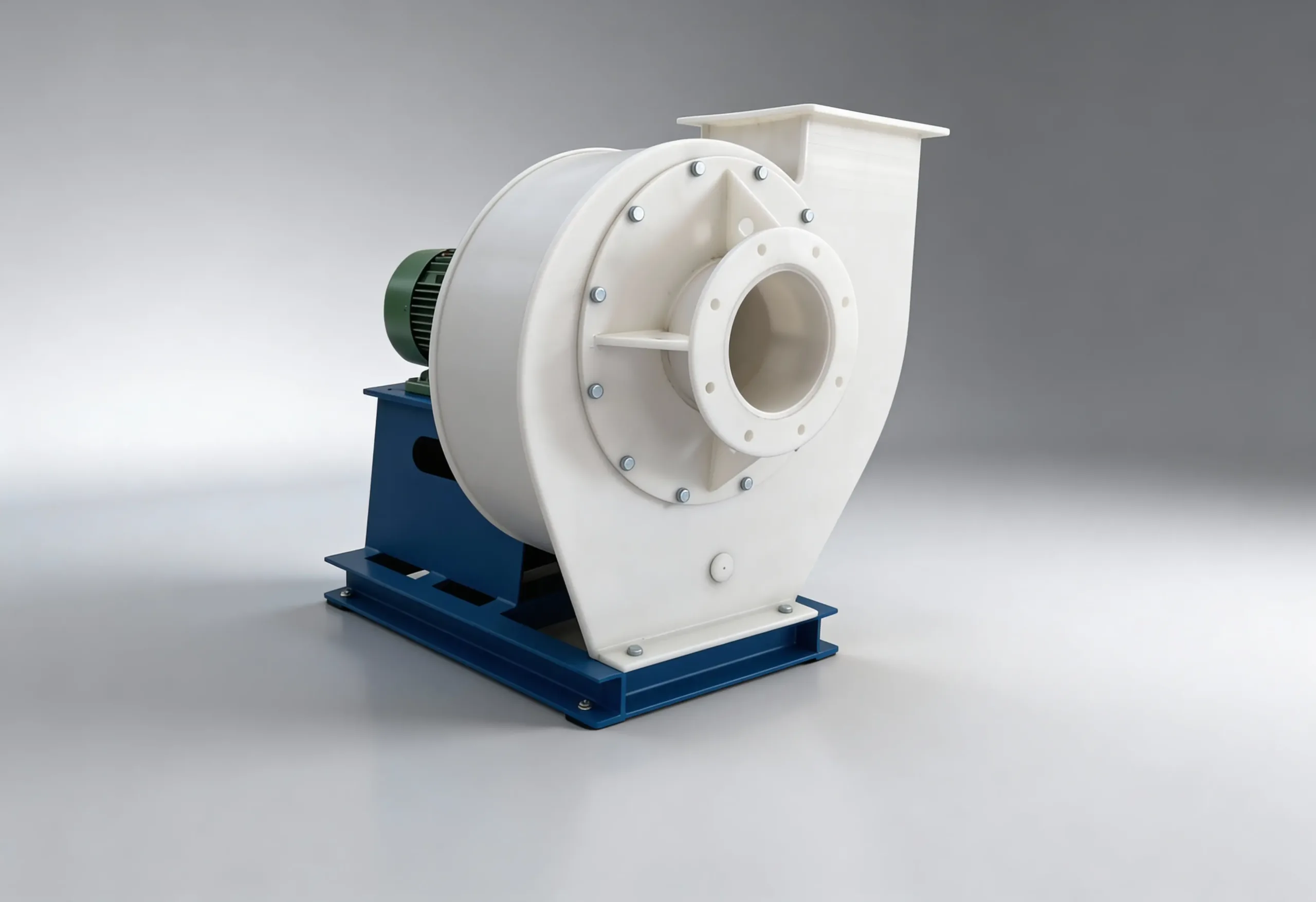

Plastic Fans

These industrial fans are manufactured from special polymer materials (Polypropylene – PP, PVC, PE, etc.) and are fully corrosion-resistant, enabling safe air transfer in challenging environments containing acidic, corrosive, and chemical gases. They are designed to operate with high performance and leak-proof sealing in harsh atmospheric conditions that standard metal fans cannot withstand.

Corrosion-defying technology backed by 25 years of experience and engineering.

Plastic Fans: A Powerful and Reliable Solution for Chemical and Corrosive Processes

In industrial facilities, the transfer or evacuation of acid vapors, toxic gases, and corrosive particles from one point to another is not possible with standard ventilation equipment. At Efsan Makina, we manufacture specially designed plastic fans that offer superior performance and maximum safety even in the harshest chemical conditions. In processes where metals deteriorate rapidly, our plastic radial fans with polymer (plastic) housing and blade structure guarantee long-lasting and uninterrupted ventilation for your facility.

Our plastic fans, which have superior sealing properties, are also supported by ex-proof (explosion-proof) motor options, fully meeting your specific plant safety standards (ATEX, etc.).

- Volumetric Flow Rate: 500 to 300,000 m³/h (cubic meters per hour)

- Pressure Difference: 7,500 Pa (Pascal)

- Efficiency Level: Up to 60%

- Operating Temperature: 0 – 80 °C

- Body Material: PP, PPs, PVC, PE, PVDF

- Impeller/Furniture Material: PP, PPs, PVC, PVDF and steel coated

- ATEX (Explosive Atmosphere Compatibility)

- High efficiency level

- Corrosion resistant

- Motor mounted outside the airflow

- Possibility of using different motors (explosion-proof motors)

- No metal parts in the airflow

- Flexible design

In addition to corrosive environments such as acids and alkalis, potentially explosive atmospheres frequently occur in the chemical and process industries; for example, due to solvents or flammable gases.

We supply ATEX-compliant industrial fans for these applications:

- Electrically energy-consuming materials

- Zone 1 and Zone 2 versions

- Documentation and design in accordance with relevant standards

This ensures you get the right solution for both corrosive exhaust air flows and potentially explosive atmospheres.

Why should you choose Efsan Makina Plastic Fans?

- Superior Corrosion and Chemical Resistance: Manufactured with premium polymer materials exhibiting high corrosion resistance against environments containing acids, bases, and aggressive chemical vapors. It enhances the safety of your facility by eliminating the risk of rust and decay.

- Maximum Energy Efficiency: Aerodynamic optimization is prioritized during the design phase. The smooth inner surface minimizes friction, allowing you to achieve high flow/pressure values with significantly lower energy consumption.

- Process-Specific Design: Instead of a single product approach, we develop turnkey plastic centrifugal fan systems tailored to your specific needs by analyzing critical parameters such as the type, concentration, temperature, and suction flow rate of the gas in your facility.

- Engineering Depth: With years of industry experience, we not only manufacture fans but also offer engineering solutions that calculate the most suitable blade angles and seal types for your chemical processes.

- Comprehensive After-Sales Support: We ensure uninterrupted production with our after-sales services, ranging from assembly and commissioning to regular maintenance and spare parts supply.

With Efsan Makina Plastic Fans, bring high efficiency, reliability, and long lifespan to your facility, even in corrosive environments. Contact our engineering team today for customized ventilation solutions for your project.

Efsan Makina Plastic Fans are used in numerous industrial applications requiring high corrosion resistance:

- Acid and Chemical Vapor Discharge: Absorption of acidic and basic gases from industrial tanks and pools.

- Gas Scrubber Systems: High-pressure redirection of toxic air flow to treatment units.

- Laboratory and Fume Hood Ventilation: Discharge of reactive gases generated in research and quality control laboratories.

- Plating and Galvanizing Pools: Emission of high-density vapor in metal surface treatment and coating facilities.

- Wastewater and Treatment Plants: Odor removal systems and biogas discharge lines.

Where standard metal fails, our plastic fans are indispensable in the following sectors:

- Chemical and Petrochemical Industry

- Pharmaceutical Industry and Laboratory Facilities

- Surface Treatment, Painting and Galvanizing Plants

- Water and Wastewater Treatment Systems

- Fertilizer and Agricultural Pesticide Production Plants

- Paper and Pulp Factories

Efsan Makina Plastic Fans are more than just a product; they are the result of our integrated engineering approach:

- Engineering / Design / Optimization: Selection of materials suitable for the chemical fluid, aerodynamic design, and efficiency optimization.

- Installation / Commissioning: Safe installation and initial commissioning service at your facility with special sealing gaskets.

- Maintenance / Service / Spare Parts Service: Regular vibration checks, balancing, and supply of original polymer spare parts.

- Testing / Measurement Service: Reporting of flow rate, pressure, and sound level performance tests according to international standards after installation.